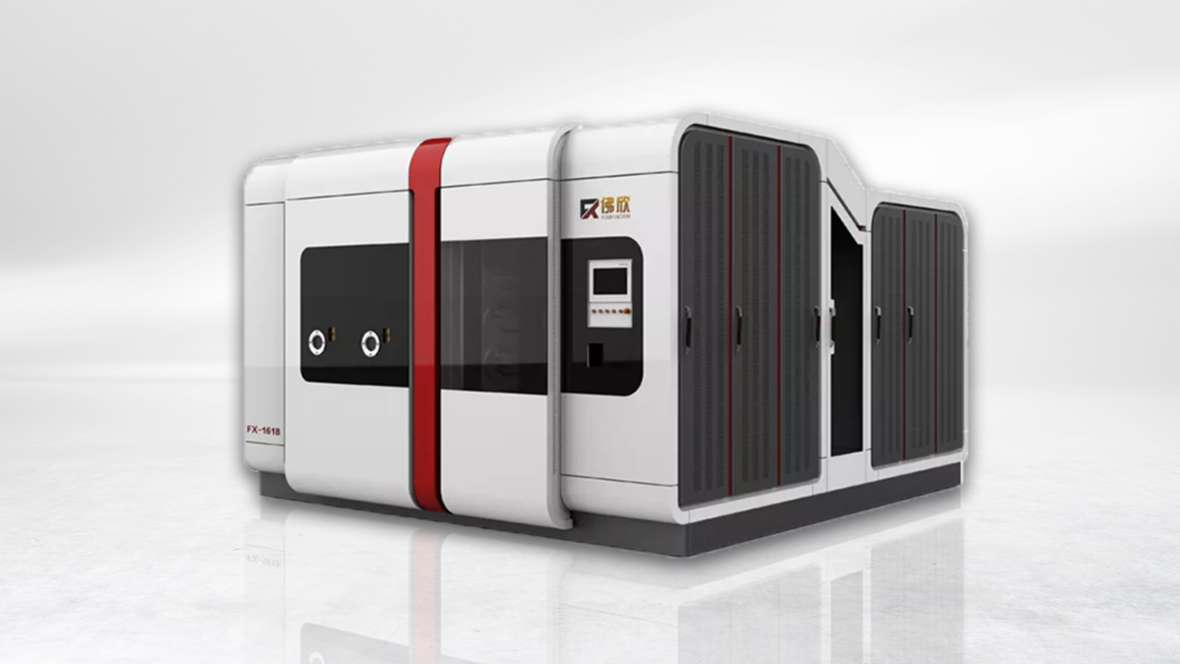

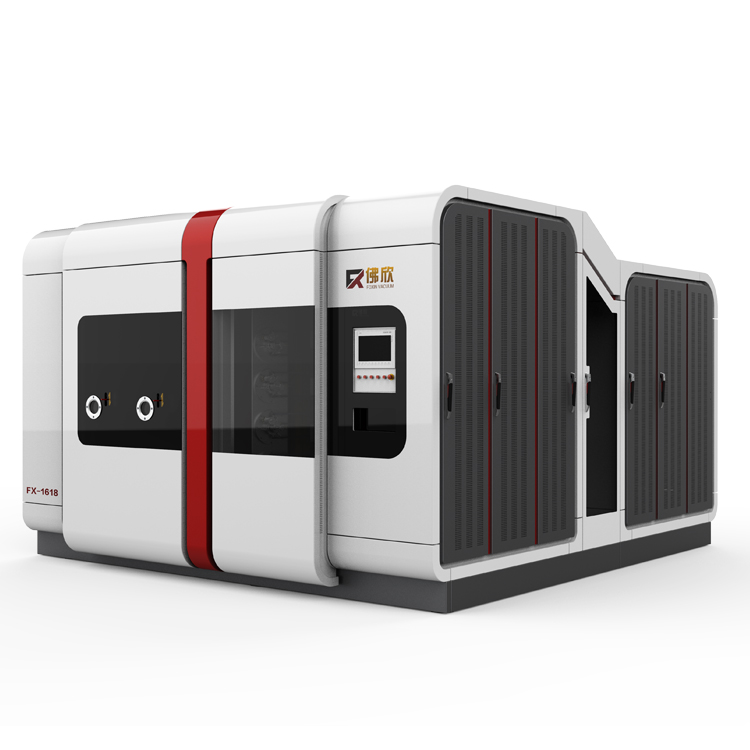

Jewelry metal chain ion PVD electroplating machine

Environmental

Customization

High quality

Delivery time

-

01 Overview

-

02 Benefit

-

03 Working Principle:

-

04 Download

-

05 Specifications

01 Overview

Jewelry metal chain ion PVD electroplating machine uses physical vapor deposition technology to cover metal chain and other jewelry with a thin layer of tough coating. The process is a bit like a sophisticated magic show, in a vacuum environment, metal materials such as gold, silver or titanium nitride are evaporated into particles, and then gently adhere to the surface of the jewelry. This not only makes the jewelry look more beautiful, but also greatly improves its durability.

This machine is particularly intimate, whether it is a small handicraft workshop, or busy large-scale production line, it can be perfectly adapted. Manufacturers can use it to create high-end jewelry with precious metal textures at a lower cost. This technology is both practical and efficient, like ordinary materials in a gorgeous coat, but also to meet the current consumer demand for durable and environmentally friendly products.

02 Benefit

Strong Durability: PVD coating than traditional electroplating wear, corrosion resistance, use a long time, daily wear is completely no problem.

Cost-Effective: Thin plating of a layer of precious metal on the common metal effect, both cost savings, without losing that high-end sense.

Environmental Protection: do not use those harmful chemicals, reduce waste, in line with the current trend of green living.

Design Flexibility: Color, texture pick, jewelry design can play more new patterns.

03 Working Principle:

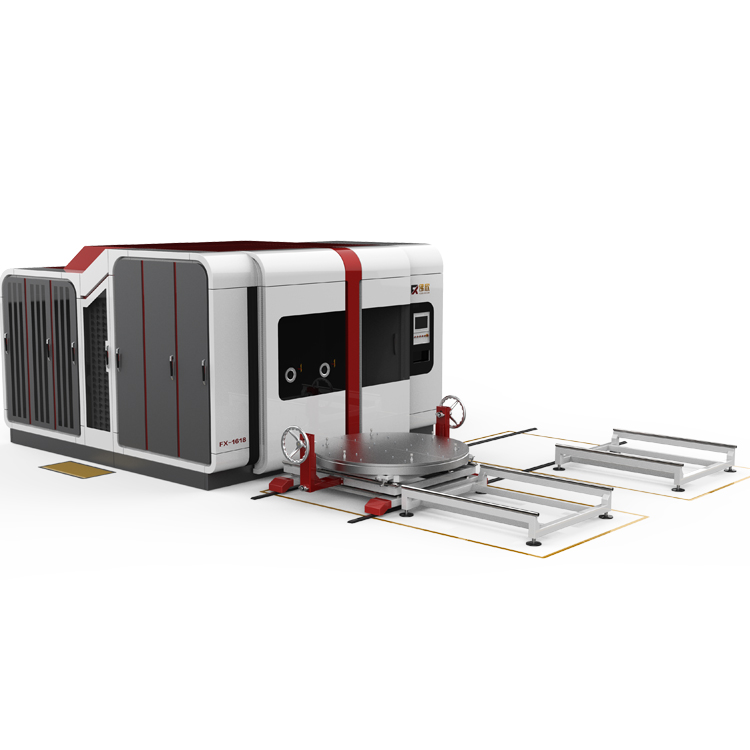

1. Preparation: Throw something like a metal chain into a vacuum chamber, pump out the air, and get a low-pressure environment so the coating process won’t be interfered with by anything outside.

2. Material Evaporation: The coating material (such as gold or titanium nitride) is turned into a gas by high temperature or ion bombardment, and small particles fly around the vacuum chamber.

3. Deposition Coating: The evaporated material is deposited on the surface of the jewelry, and then forms a strong bond with the substrate, and finally produces a uniform and durable thin coating, which must be completed under precise control to ensure quality and consistency.

04 Download

Vacuum coating overview

05 Specifications

| Model(FOXIN) | FOXIN-PVD-0708 | FOXIN-PVD-0809 | FOXIN-PVD-0910 | FOXIN-PVD-1012 | FOXIN-PVD-1212 | FOXIN-PVD-1215 |

| Vacuum Chamber Size(mm) | Ф700×H800mm | Ф800×H900mm | Ф900×H1000mm | Ф1000×H1200mm | Ф1200×H1200mm | Ф1200×H1500mm |

| Industry | Watch industry, 3C industry, hardware industry, precision mold industry, tool industry, etc | |||||

| Product | Case watchband, drill, hard alloy, milling cutter, punching rod standard parts die, forming die, etc | |||||

| Coating Film Type | Titanium nitride , Titanium nitride carbide, Zirconium nitride , Chromium nitride , Titanium aluminum nitride ,Titanium carbide | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 6set-8set | 6set-8set | 8set-12set | 8set-12set | 10set-14set | 10set-14set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 30KW/1set | 30KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 2set-3set | 2set-3set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | |||||

| Gas | Argon, nitrogen, oxygen, acetylene, etc | |||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||