Pvd Ceramic Tiles Sputtering Coating Machine For Sale

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Working Principle

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

Meet the Stainless Steel Sheet Gold PVD Coating Machine—your go-to solution for turning ordinary stainless steel into something extraordinary. This isn’t just another piece of coating machinery; it’s a game-changer built around the PVD coating process. Using physical vapor deposition, it lays down a thin, tough layer of gold PVD that’s as beautiful as it is durable.

Want that luxurious gold-coated shine or a subtle matte vibe? You’ve got it. This machine is all about giving you standout metal finishing without the hassle—think sleek stainless steel gold plating that lasts. Whether you’re crafting high-end designs or leveling up your production, this PVD machine delivers the kind of quality that makes your work shine. Ready to see what it can do for you?

02 Working Principle

Loading: You start by setting your stainless steel sheets onto a holder inside the vacuum chamber. It’s all about getting them lined up just right for the coating to stick perfectly.

Vacuum: The chamber seals up and the vacuum technology kicks in, pulling out air and any stray particles. This keeps the PVD coating process clean and on point.

Sputtering: Things heat up here. Gold material turns into a vapor, and a burst of plasma charges it up. The sputtering process then sends those charged bits flying onto the steel surface with pinpoint accuracy.

Deposition: When those gold particles hit the steel, they build up a sleek gold PVD coating. You can tweak the magnetron sputtering settings—like power or gas flow—to get the exact thickness you’re after.

Finishing: Once it’s done, the chamber opens up, and out come your gold-coated stainless steel sheets. That’s metal finishing that looks good and lasts long.

03 Main Application

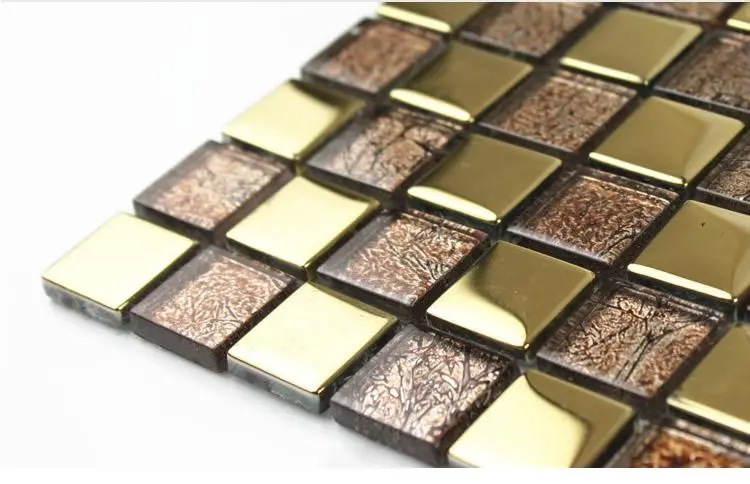

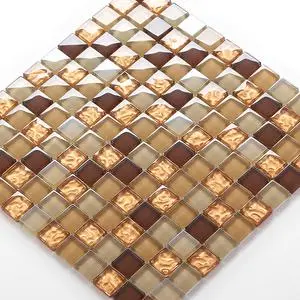

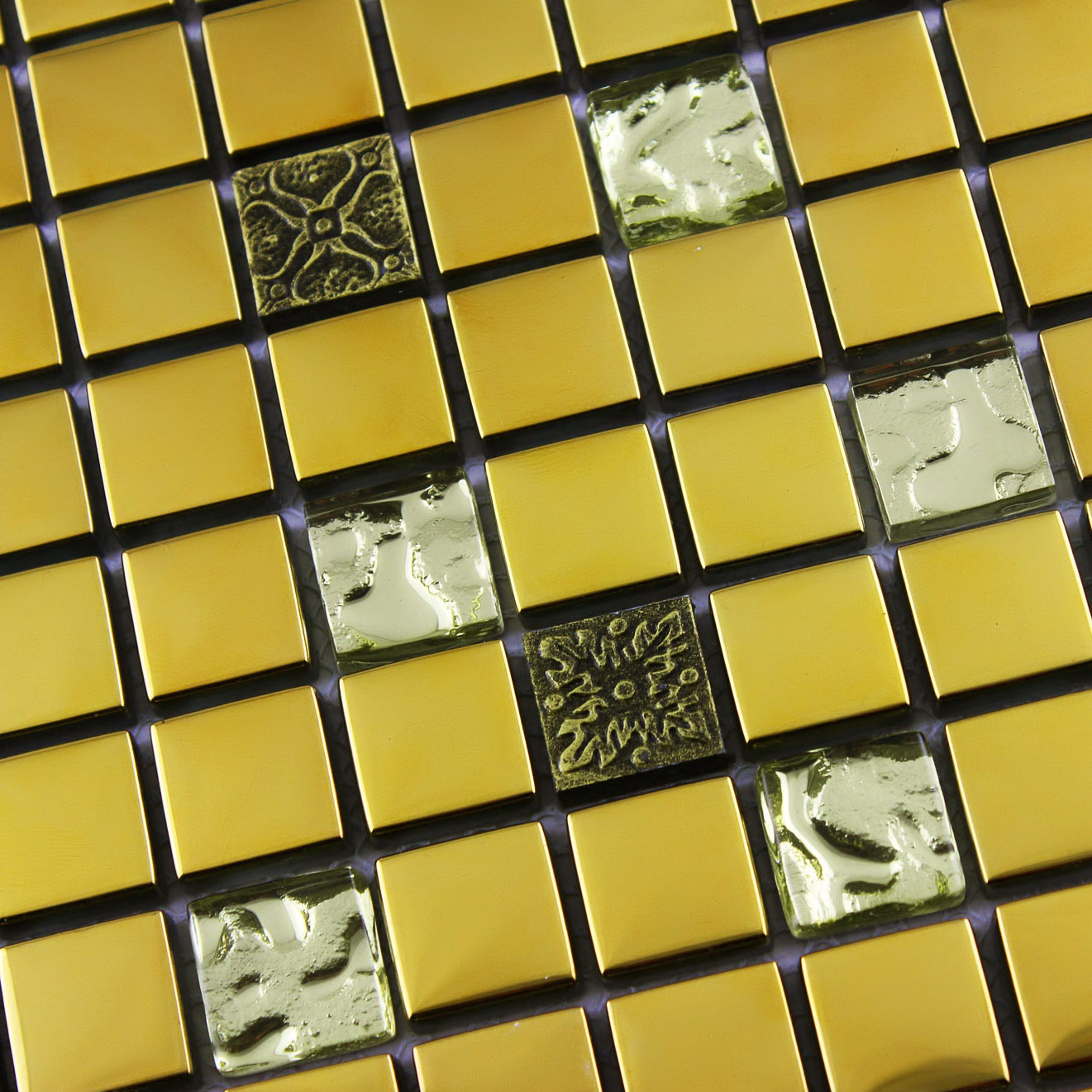

1. Decorative Coating: This machine lays down stunning PVD coatings on stainless steel sheets, turning them into eye-catching pieces. Whether you’re going for bold patterns or sleek designs, it’s all about making things look good while boosting durability with that gold PVD finish.

2. Wear-Resistant Coating: Need something tough? It deposits a metal coating that stands up to wear and tear, giving your stainless steel sheets a longer life. Perfect for keeping your projects in top shape over the long haul.

3. Anticorrosive Coatings: Harsh conditions won’t stand a chance. The PVD coating process adds a protective layer to your sheets, guarding against corrosion and keeping that gold-coated look pristine no matter what the environment throws at it.

04 Download

Vacuum coating overview

05 Specifications

| Model | TG-1418 | TG-1620 | TG-1820 | TG-2020 | TG-2023 | TG-2030 |

| Chamber Size(mm) | Ф1400×H1800mm | Ф1600×H2000mm | Ф1800×H2000mm | Ф2000×H2000mm | Ф2000×H2300mm | Ф2000×H3000mm |

| Application | Hardware industry, sanitary appliance industry | decoration industry, household appliances industry | Faucet, stair handrail, household appliances | LOGO signs, stainless steel frame | stainless steel parts and plate, etc | |

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver/Colorful | Sapphire orchid | Rose red, black and so on |

| Vacuum Chamber | equip with pumping system and water cooling system | Vertical door, hanging or horizontal cart structure | ||||

| Vacuum System | Sustaining Pump +Mechanical Pump + Roots Pump + Diffusion Pump | Molecule Pump(specific model according to customers' requirements) | ||||

| Vacuum | 1 set pirani | 1 set cold cathode | 1 set diaphragm gauge | |||

| Supply Type | DC power | MF power, | pulse power(bias power, arc power) | |||

| Ultimate | 1.0-6.0x10-4Pa | Non-loading cooling | ||||

| Arc Source | 16-24 set | 16-24 set | 18-26 set | 18-26 set | 22-28 set | 22-28 set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power | 40KW/1 set | 40KW/1 set | 40KW/1 set | 50KW/1 set | 50KW/1 set | 60KW/1 set |

| Magnetron Power Supply | 1-2 set | 1-2 set | 2-3 set | 2-3 set | - - | - - |

| Rotation | Mult-axis planetary with frequency control | Can be controlled and adiustec | ||||

| Baking | Normal temperature ~300C can be controlled and adjusted(PID temperature control) | |||||

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | ||||

| Cooling Method | Water cooling circulation | equip with industrial cooling tower | industrial water chiller(refrigerating machine) | cryogenic system(customers provide) | ||

| Controlling | Manual | half-auto, auto | touch screen operation | PLC or computer controlled | ||

| Supply Index | Air Pressure 0.5-0.8MPa | Water Temperature<25C | Water Pressure>0.2MPa | |||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happensand carry out related protect solution and electric interlock. | |||||

| Total Power | 100~125KW | 125~145KW | 145~165KW | 165~185KW | 185~200KW | 200KW |

| Output | Voltage 220V,Frequency 50Hz(equip as customers' national electricity standard) | |||||

| Occupation | 15~50㎡ | 15~50㎡ | 25~55㎡ | 25~55㎡ | 35~55㎡ | 35~55㎡ |

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | |||||