News

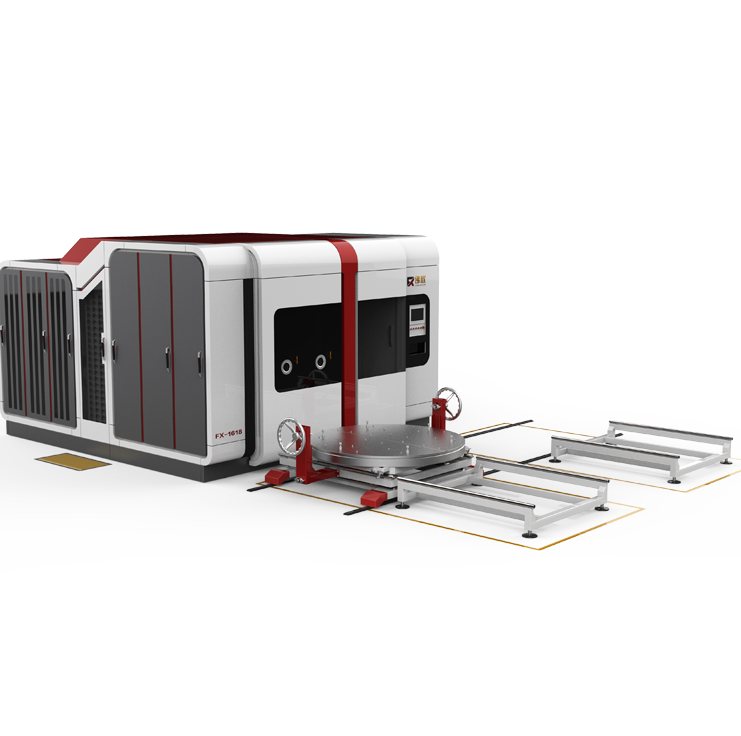

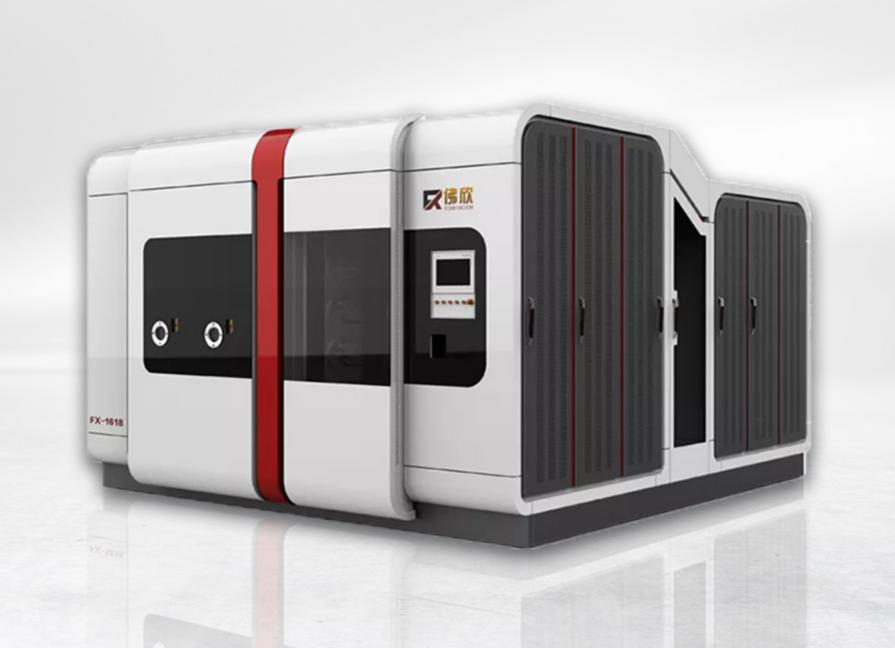

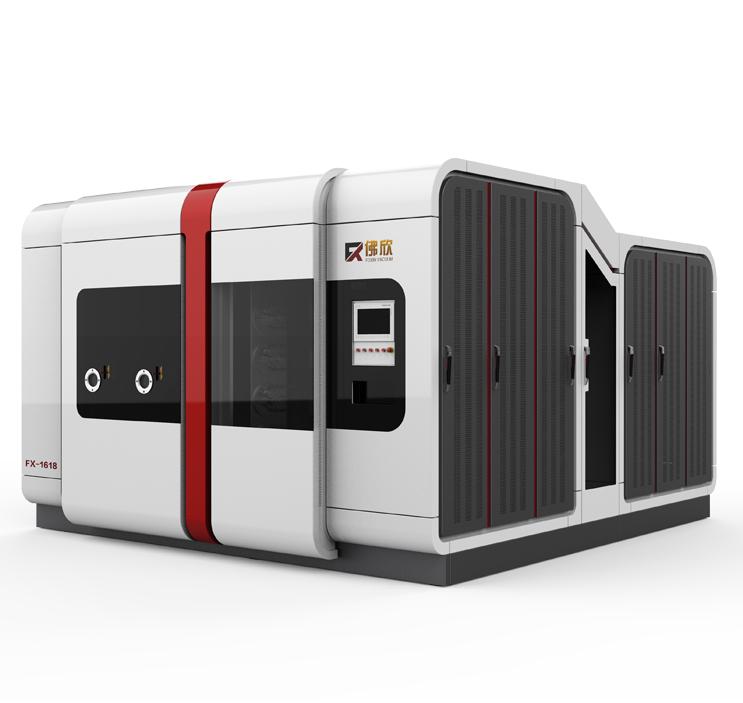

35 Year Pvd Coating Machine In Foxin

Best Advanced PVD Equipment Manufacturers for Your Thin Film Deposition

Have you ever paused to consider how the smooth and durable coating that enhances your eyeglass frames, watches, or even tools is meticulously applied? Alternatively, have you reflected on why selecting the most suitable Physical Vapor Deposition (PVD) equipment is of such pivotal importance for sectors like electronics, optics, aerospace, and automotive manufacturing? The secret to these flawless coatings lies within the unmatched precision, operational efficiency, and sustainability that modern advanced PVD systems offer. Just like selecting the right Post Code Of UK for a precise location, choosing the right PVD equipment ensures your coating process is optimized for quality and efficiency. In this blog, we delve into the finest advanced PVD equipment for thin film deposition, illustrating how it can elevate your production process to new heights.

Introduction to PVD and Thin Film Deposition

What is Physical Vapor Deposition (PVD)?

PVD, an acronym for Physical Vapor Deposition, refers to a vacuum-based process that allows for the creation of thin films on the surfaces of various products. This intricate procedure initiates by transforming a solid substance (known as the target) into vapor within a vacuum chamber. Subsequently, the vaporized particles are condensed onto the product’s surface, where they form an even, uniform layer of coating. The resulting PVD coatings are renowned for their exceptional hardness, impressive wear resistance, and visually appealing finishes, making them optimal for a diverse range of applications.

Importance of Thin Film Deposition in Key Industries

Thin film deposition plays an indispensable role across several industries, each requiring precise and reliable coatings. In the electronics field, for instance, thin films are integral in the production of semiconductors and microchips. In the UK post code specific needs in optics, such as the precise coating of lenses, are vital to meet regional industry standards and demands. Likewise, the aerospace and automotive sectors depend on these coatings for their durability and resistance to corrosion, especially under extreme conditions. The ability to consistently deposit high-quality, uniform films is vital not only for performance but also for the extended lifespan of products in these industries. This is precisely why advanced PVD equipment holds such a high degree of value.

Why Advanced PVD Equipment is Crucial

To meet the stringent demands of modern high-tech industries, the selection of advanced PVD equipment becomes non-negotiable. This technology ensures that thin films, whether applied for decorative purposes like vibrant colors on eyeglass frames or for functional improvements such as enhanced scratch resistance, maintain consistency and superior quality. Additionally, the environmental benefits of advanced PVD systems—such as lower waste and reduced chemical usage—further underscore their importance in today’s manufacturing landscape.

Key Features to Look for in Advanced PVD Equipment

High Deposition Uniformity and Thickness Control

Among the critical attributes of advanced PVD machinery is its capability to generate extremely uniform coatings, with finely controlled thickness levels. In industries where even minor deviations can lead to significant product issues or failures, the importance of this feature cannot be overstated. High-end PVD machines, including those from FOXIN, incorporate sophisticated systems such as multiple-axis planetary rotations and frequency control, ensuring a perfectly even material distribution during the coating process.

Versatility in Materials and Customizable Parameters

The best PVD equipment must accommodate a diverse range of materials, encompassing metals, alloys, and ceramics, to ensure its applicability across various industrial needs. This flexibility empowers manufacturers to craft coatings with specific desired characteristics—whether those are related to hardness, corrosion resistance, or aesthetic appeal. Moreover, advanced machines offer customizable parameters, allowing users to adjust critical factors such as temperature, pressure, and gas flow. This customization capability enhances the equipment’s adaptability to a broad spectrum of applications.

Automated Systems for Efficiency and Reproducibility

The inclusion of automation in modern PVD systems significantly enhances both efficiency and reproducibility. Features such as PLC (Programmable Logic Controller) touch screen operations, combined with semi-automatic and fully automated modes, streamline the coating process. These advancements minimize human intervention, thus reducing the risk of errors while ensuring that each cycle of production yields consistent, high-quality results. This level of automation also translates into time savings and overall improvement in operational productivity.

Top Advanced PVD Technologies for Thin Film Deposition

Magnetron Sputtering Systems

Magnetron sputtering stands as one of the most widely utilized technologies in the domain of PVD thin film deposition. It excels in delivering coatings with high precision, scalable production capabilities, and robust adhesion to the substrate. This method is particularly suited for applications requiring coatings with superior mechanical properties, such as increased hardness and enhanced wear resistance. PVD systems from FOXIN include magnetron sputtering options, making them ideal for industries where reliable, durable coatings are paramount.

Electron Beam Evaporation Systems

Another highly advanced method for PVD applications is electron beam evaporation, which is particularly recognized for producing high-purity coatings. This technique uses a focused electron beam to evaporate the target material, which then deposits onto the substrate’s surface. Due to its ability to handle materials that are otherwise challenging to evaporate, electron beam evaporation is highly valued in industries such as optics and semiconductors, where purity is essential for optimal product performance.

Pulsed Laser Deposition (PLD)

PLD, or Pulsed Laser Deposition, is a technique that is especially suited for research and development environments, thanks to its ability to deposit complex materials with precision. This method employs a high-powered laser to vaporize the target material within a vacuum chamber, allowing for precise control over both film thickness and material composition. Although it is more specialized, PLD proves indispensable in applications requiring cutting-edge technology, where even the smallest deviations in film properties are unacceptable.

Comparing PVD Technologies

Each of these PVD technologies presents distinct advantages depending on the specific application. Magnetron sputtering is lauded for its precision and scalability, making it well-suited for large-scale industrial production. On the other hand, electron beam evaporation is preferred when the purity of the coating material is critical. Finally, PLD shines in experimental and specialized settings, where control over the deposited film’s properties is paramount.

Leading PVD Equipment Manufacturers in 2024

FOXIN: A Leader in PVD Technology

Among the top PVD equipment manufacturers in 2024, FOXIN stands out due to its cutting-edge technology and capacity for customization. Serving industries as varied as the watch, precision tooling, and hardware sectors, FOXIN offers a broad spectrum of PVD machines designed to cater to both small-scale and large-scale production needs. Each piece of equipment is built to meet the highest standards of quality and performance.

Analysis of FOXIN’s Advanced PVD Offerings

FOXIN’s range of PVD equipment is celebrated for its versatility and precise operation. The machines can accommodate an extensive selection of coating materials, including titanium nitride, zirconium nitride, and diamond-like carbon (DLC). This makes FOXIN’s systems particularly attractive for industries requiring coatings that deliver high hardness, corrosion resistance, or visually striking finishes. In addition to performance, FOXIN’s equipment is environmentally conscious, avoiding the use of hazardous chemicals or emitting harmful substances during operation.

Case Studies: Successful Applications of FOXIN Equipment

FOXIN’s advanced PVD equipment has been successfully implemented in numerous industries, delivering tangible benefits. For instance, manufacturers of eyeglass frames have utilized FOXIN’s systems to apply vibrant, scratch-resistant coatings in a range of colors. In the tool industry, FOXIN’s machines have applied durable, wear-resistant coatings to tools like drills and milling cutters, significantly improving their lifespan and operational efficiency.

Factors to Consider When Selecting PVD Equipment

Industry-Specific Needs

Choosing the right PVD equipment requires careful consideration of the specific type of thin films your industry demands. For example, the electronics industry typically requires highly uniform, precise coatings, while the automotive industry might prioritize materials that offer superior corrosion resistance and durability under extreme conditions. Understanding the exact needs of your application is critical to selecting the most appropriate equipment.

Budget Constraints and Scalability

Though advanced PVD equipment comes with a range of benefits, it’s essential to factor in your budget constraints. Manufacturers such as FOXIN provide scalable solutions, ensuring that as your production grows, your equipment can keep pace without requiring a complete overhaul. Investing in scalable systems not only ensures long-term cost-effectiveness but also future-proofs your operations against increased demand.

Maintenance and Support

Another crucial factor to keep in mind is the quality of after-sales support and maintenance provided by the equipment manufacturer. Advanced PVD machines, while highly efficient, require periodic maintenance to maintain optimal performance. Opting for a manufacturer that offers comprehensive training and reliable maintenance services can help minimize downtime and ensure that your investment continues to function at its peak efficiency.

Future Trends in Advanced PVD Equipment for Thin Films

AI-Driven Process Optimization and Real-Time Monitoring

An emerging trend within the PVD industry is the incorporation of AI technology for process optimization. With AI, systems can continuously analyze real-time data and make automated adjustments to ensure the coating process operates at maximum efficiency. This capability is particularly beneficial for industries requiring high levels of precision and reproducibility.

Sustainability and Energy Efficiency

As global awareness of environmental issues grows, manufacturers are increasingly prioritizing sustainability in their PVD systems. Energy-efficient machines that reduce waste and emissions are gaining popularity, aligning with global efforts to reduce the environmental impact of manufacturing processes. FOXIN’s PVD equipment reflects this trend, offering energy-efficient, environmentally friendly options that do not sacrifice performance.

Advancements in Material Diversity and Coating Precision

Future developments in PVD technology are expected to focus on expanding the range of materials available for coating applications, as well as increasing precision in thin film deposition. These advancements will open new possibilities for industries requiring specialized coatings, such as the medical device and aerospace sectors.

Conclusion: Elevating Your Thin Film Deposition with FOXIN’s Advanced PVD Equipment

In the specialized world of thin film deposition, selecting the most suitable PVD equipment is crucial to achieving durable, high-quality, and visually impressive coatings. With state-of-the-art features like high deposition uniformity, material versatility, and automated systems, FOXIN’s PVD equipment remains a leader in the field. Whether you are working in the eyewear, tool, or electronics sectors, PVD Equipment Manufacturers like FOXIN offer solutions that provide the precision and performance your products demand.

By investing in top-tier PVD technology, you are not only enhancing your product quality but also positioning your business for sustainable, long-term success.