What Is the Metal Coating?A Film Work

In our daily life,We always find many metal materials show the most beautiful appearance to us. Do you know the metal material how to show this color? We will introduce the PVD coating craft to you. The PVD coating is widely used on metal products like stainless steel,tableware,auto parts,precision tools,etc. In order to make metal products shows more durable and beautiful.

How To Metal PVD Coating

Metal coating is a technique for depositing metal or metal compounds onto the surface of a substrate by physical means. The core of this is to use physical processes such as evaporation, sputtering or ion injection in a vacuum environment to convert the coating material into gaseous atoms or ions, and deposit them on the surface of the substrate to form a thin film. The process does not involve the use of chemical reaction, hence the name physical vapor deposition.

Metal PVD coating basic technological process including pretreatment, coating and after-coating of three stages. Pretreatment stage is to clean the substrate, remove oil and deoxidize the skin to ensure combination of the coating layer. Coating stage is to convert the coating material into gaseous atoms or ions by evaporation source or sputtering target. Deposit them on the surface of the substrate to form a thin film. After-coating stage is the necessary heat treatment, polishing or etching of the coating layer to improve its performance or beauty.

The PVD Metal Coating in Stainless Steel Products

Stainless steel is widely used in various fields because of its excellent corrosion resistance and durability. However, the surface of stainless steel still need to be further improved in some specific environments. Metal PVD coating technology has been developed to meet this demand.

The application of PVD coating on stainless steel products can significantly improve the surface hardness, wear resistance and corrosion resistance. At the same time,adjusting the composition and process parameters of coating material, also can have different color, luster and the surface of the texture effect to meet the demand of personalized decoration. In the field of decoration such as stainless steel doors and windows, handrails, metal PVD coating technology is widely used to improve the beauty and durability of products.

Benefits of PVD Coating on Stainless Steel Products

1.Rich the colour of stainless steel

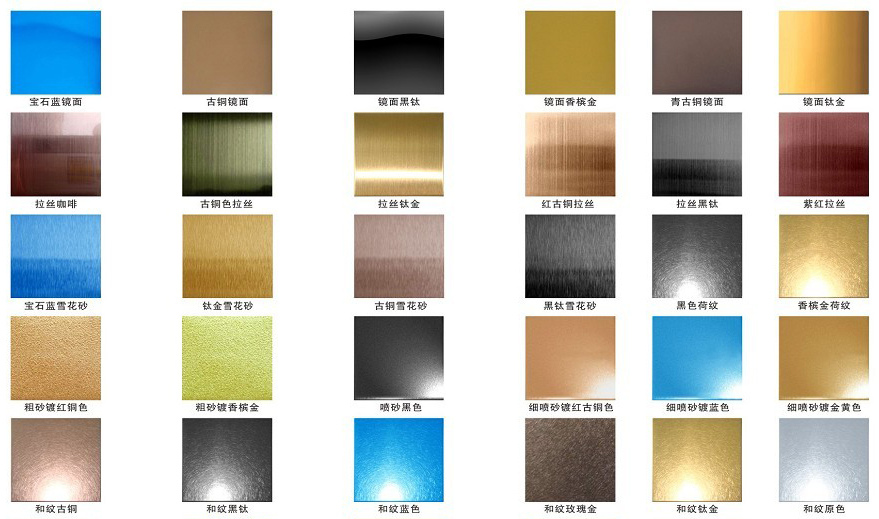

- PVD coating can have a variety of color effects, such as gold, rose gold, black titanium, copper, silver, and even some special colors, such as rainbow or gradient color.

- Through different film and craft, stainless steel can be given unique color and appearance, making the product appearance more attractive.

2.Improve surface hardness

- PVD coating can not only change the color of stainless steel, but also increase its surface hardness.

- The PVD coated surface is more resistant to scratch and wear, extending the service life of the product,especially suitable for high frequency accessories and products, such as mobile phone shell, watches, kitchen utensils…..

3.Improve corrosion resistance

- PVD coating can form a dense protective film on the surface of stainless steel, effectively preventing oxidation and corrosion, especially in wet or chemical contact environment, so that stainless steel products still maintain appearance and performance under harsh conditions.

4.Delicate process effect

- PVD process can provide more uniform and fine surface treatment effect for stainless steel products.

- The brushed preserves the original texture of the stainless steel, further improving the gloss and stain resistance of the surface.

Metal Pvd Coating in the Application of Tableware

Tableware as an indispensable item in daily life, its security and aesthetic degree is equally important. The application of metal PVD coating technology in tableware manufacturing improves the durability and corrosion resistance of tableware.

When zirconium nitride and other carbide materials after PVD coating treatment, tableware surface obtained higher hardness and wear resistance. In this way, the tableware is not easy to scratch during use and can maintain good appearance.

1.Improve durability

- PVD coating technology can form a dense and hard film on the surface of the tableware, which can effectively resist daily wear and scratches to extend the service life of the tableware.

- Tableware after coating has better corrosion resistance, resistant to acid and alkali in food composition on the erosion of tableware.

2.Improve convenience

- The PVD coated tableware surface is smoother and less susceptible to food debris and oil, making cleaning easier and faster.

- The coating layer has a certain self-cleaning function, which can reduce the frequency and difficulty of daily cleaning.

- PVD coating can improve the touch of the tableware surface, making it more delicate and soft.

- This helps to improve the comfort of the user when holding the tableware, reducing the feeling of fatigue caused by long-term use.

Application in the Auto Parts

With the rapid development of the automobile industry and the continuous improvement of consumers requirements for automobile performance. The application of metal PVD coating technology in auto parts manufacturing is increasingly widespread.

In automotive parts, such as engine parts, brake systems, transmission systems and other key components, metal PVD coating technology is used to improve their wear resistance, corrosion resistance and fatigue resistance. By coating treatment the surface hardness of these parts is significantly increased, which can resist long-term wear and corrosion erosion. Coating has good lubrication performance can reduce friction and wear between the parts to improve the operation efficiency of vehicle.

In addition, metal PVD coating technology is also used in the manufacture of automotive decorative parts. Through coating treatment, the surface of the decorative parts can show bright luster and rich color effects, and improve the grade and beauty of the vehicle. This makes the metal PVD coating technology also has a broad application prospect in the field of automobile personalized customization and modification.

Application of Metal Pvd Coating in Precision Cutting Tools

In the field of precision tool manufacturing, metal PVD coating technology also plays an important role. Precision tools require high hardness, high wear resistance and high impact resistance to ensure sharp cutting edges and stable cutting performance during the cutting process.

PVD coating can improve hardness and wear resistance of the tool by depositting a film on the tool surface. At the same time, the coating layer also has good lubrication performance, which can reduce the friction and wear between the tool and the workpiece, reduce the cutting force and cutting temperature, and improve the cutting efficiency and processing quality.

In precision tools, such as milling cutters, drills, turning tools, etc., metal PVD coating technology is widely used to improve the service life and cutting performance of tools. Through coating treatment, the surface hardness of the tool is significantly increased, which can resist wear and corrosion during long-term cutting. At the same time, the coating layer can also protect the cutting edge of the tool from damage and maintain its sharp cutting performance. This makes the metal PVD coating technology has a wide range of applications in the field of precision machining and high efficiency machining.

Metal PVD coating technology, as an advanced metal surface treatment technology, has become an indispensable part of industrial manufacturing with its unique advantages and wide application fields. In the application of stainless steel products, tableware, auto parts and precision tools, metal PVD coating technology not only improves the performance and beauty of the product, but also brings a broader market prospect and development space.