ABOUT US

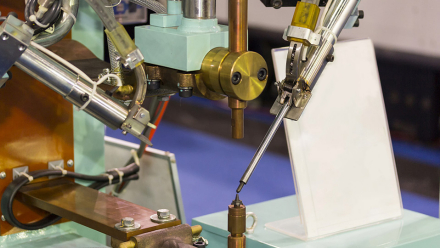

Vacuum coating equipment coating technology, is the most common daily, is also the most simple coating technology, such as AL plating, magnesium fluoride, zinc sulfide and other materials, film layer requirements are not high, are using resistance evaporation vacuum coating equipment plating, because of its cheap equipment, high production capacity, fast efficiency, simple process, so the type of equipment application is very common, is also popular.

Home /

Watch Rose Gold Color Vacuum Ion Metallizing

Watch vacuum coating utilizes a special process in a va … Read more

Read More

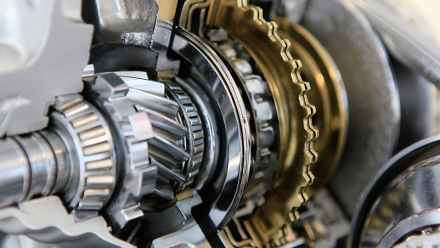

Difference between water plating and vacuum plating

First we need to understand the fundamentals of each of … Read more

Read More

Exploring the uses of PVD in different industries

Exploring the uses of PVD coating is extremely importan … Read more

Read More