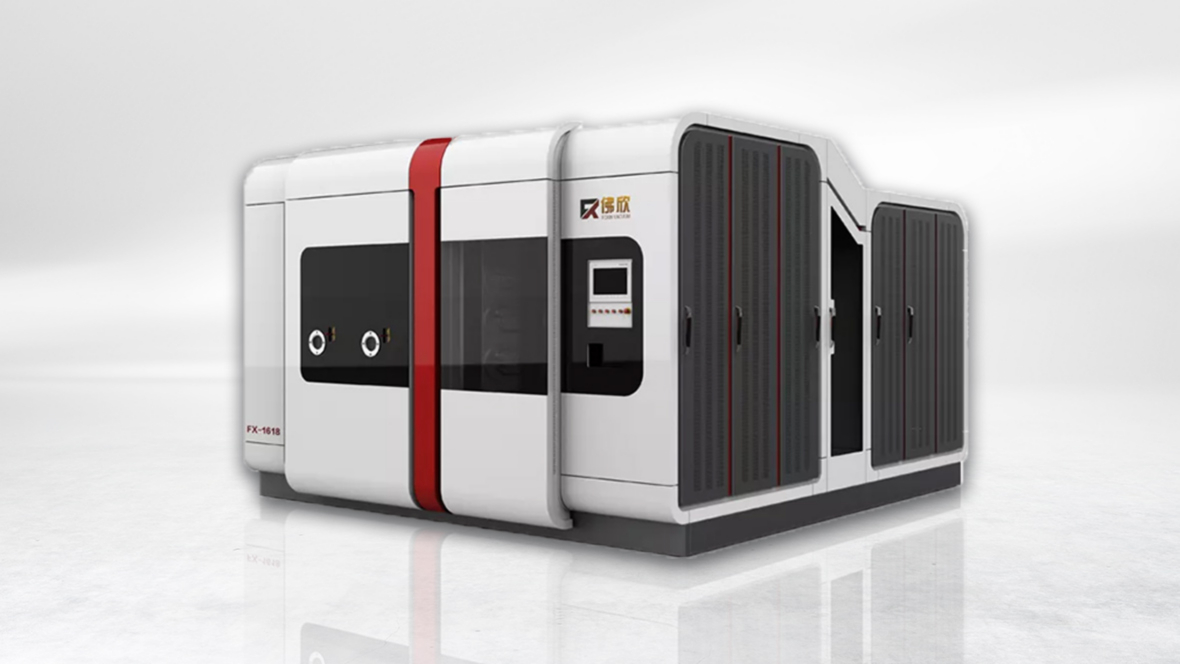

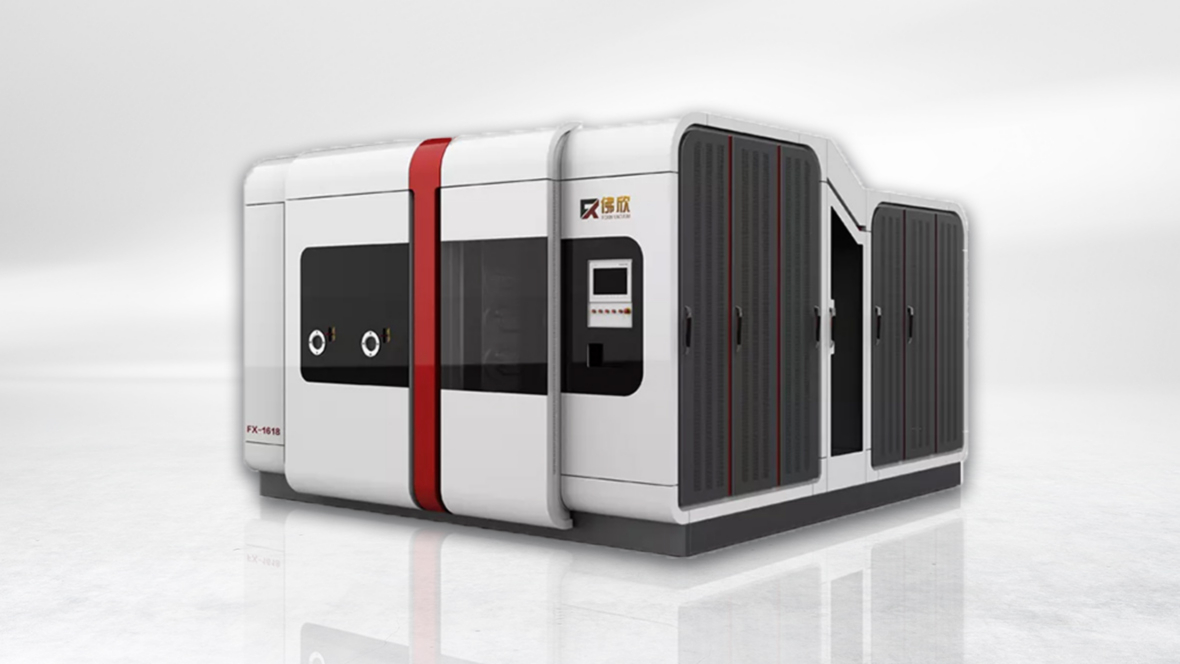

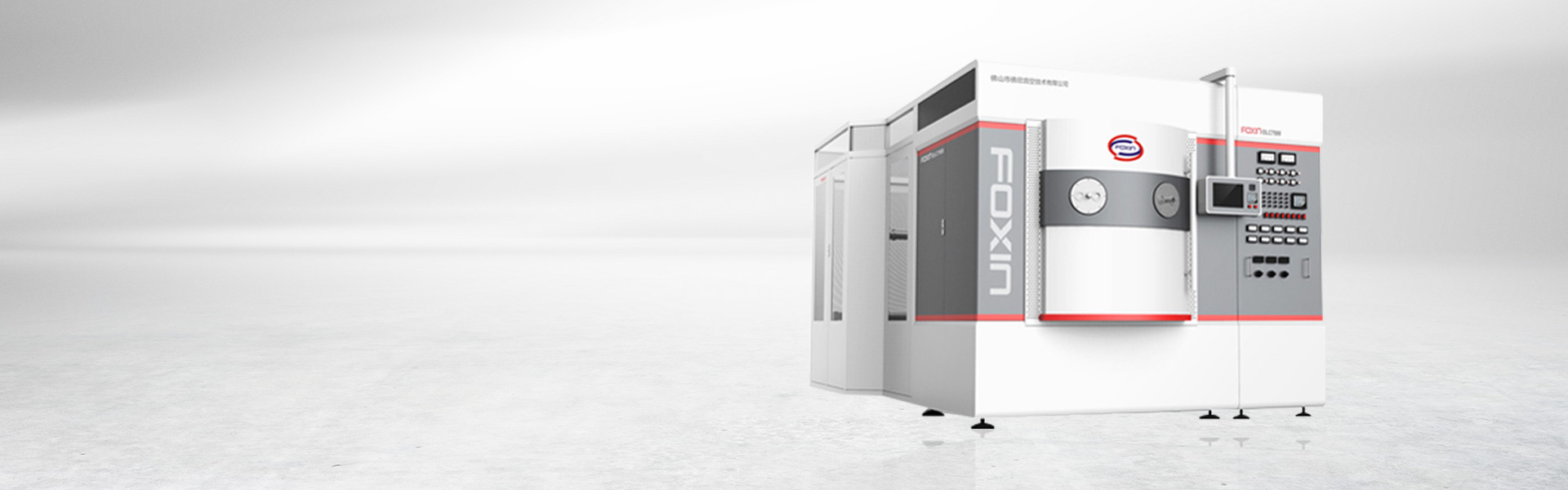

FOXIN-IP Magnetron Ion Sputtering Coating Machine

Professional coating technology more than 30 years

FOXIN-IP Magnetron Ion Supttering Coating Machine

The Foxin IP-(Magnetron Sputtering) is a common thin film precipitation technology that is widely used in many industries. The following are some of the major applications of magnetron ion sputtering industries:

Optical films: Magnetron ion sputtering is used to manufacture optical films, such as films in glasses, sunglasses, optical lenses and display devices. The technology works. Modern thin coatings of high quality, average thickness and controllable optical properties.

Electronic industry: Magnetron ion sputtering is widely used in semiconductor device manufacturing and aggregation circuit (IC) manufacturing. It is used for the deposition of metal electrodes, metallized layers, spacers and protective layers. In addition, magnetron ion beams can also be used to make magnetic materials and magnetic memory precursors.

Solar cells: Magnetron ion sputtering is used to create transparent guided oxygenate (TCO) layers and metal reflectors in solar cells. These layers help provide high solar cell absorbance and photoelectric conversion efficiency.

Automotive industry: Magnetron ion sputtering technology is used in the automotive industry to manufacture tools with scratch-resistant, corrosion-resistant and decorative coating layers. Automotive body and interior components that provide beauty and durability.

Tool coating: Magnetron ion sputtering is widely used in tool coating, such as cutting tools (drills, copper knives, cutters) and models. By depositing a hard coating layer on the tool surface, cutting efficiency can be improved, tool life can be extended and wear resistance can be improved.

Medical devices: Magnetron ion sputtering is used as a coating for medical devices, such as body parts, dental instruments and external technology tools. These coatings can provide bacterial resistance, biorelevance and corrosion resistance, transforming the service life and sexual performance of the device。

Reduce Costs

By having our own production line and a team of experienced technicians, we are able to minimize manufacturing costs and achieve a lower cost structure.

Reduce Impact

Our thin-film method reduces our environmental impact by not requiring the use of dangerous chemicals.

Custom Colors

We have the ability to create distinctive products that distinguish themselves from the competition by creating new colors or useful coatings.

Simplify

Your supply chain can be made simpler by internally coating your products.

EQUIPMENT APPLICATION

-

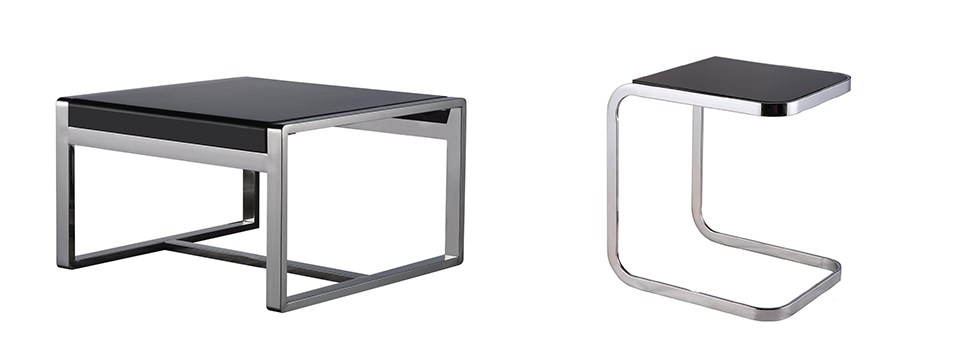

Stainless Steel

-

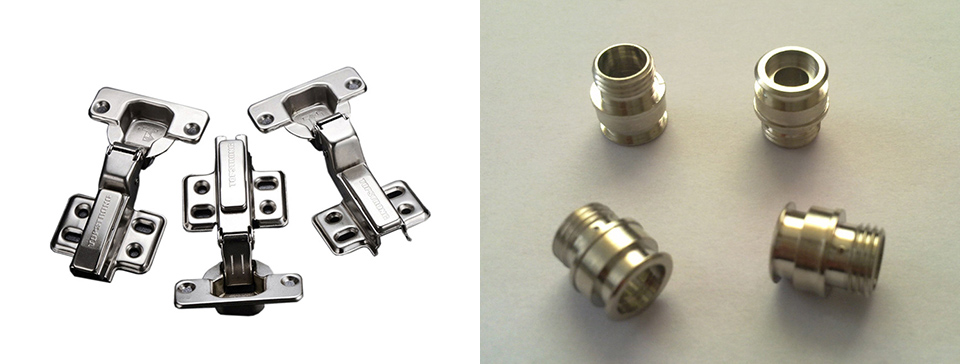

Metal

-

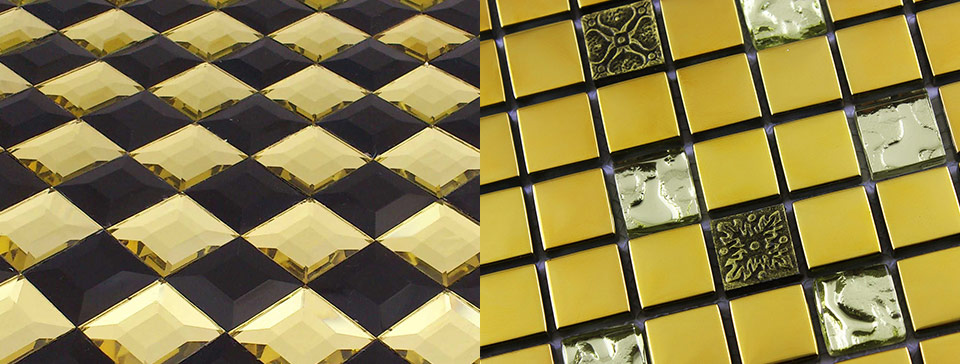

Ceramic

-

Glass

-

Plastic

{{ pro_list_app_nav_title || 'Stainless Steel' }}

-

Display Shelf

-

Furniture

-

Machine part

-

Door handle

-

Ceramic-Tile floor

-

Arts And Crafts

-

The Crystal

-

Lamp Act The Role Ofing

-

Frames

-

Following From

-

Auto Parts

Would you like to know more?

To provide you with the best quality service is our commitment