Gold Pvd Coating Equipment

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Gold Pvd Coating Features:

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

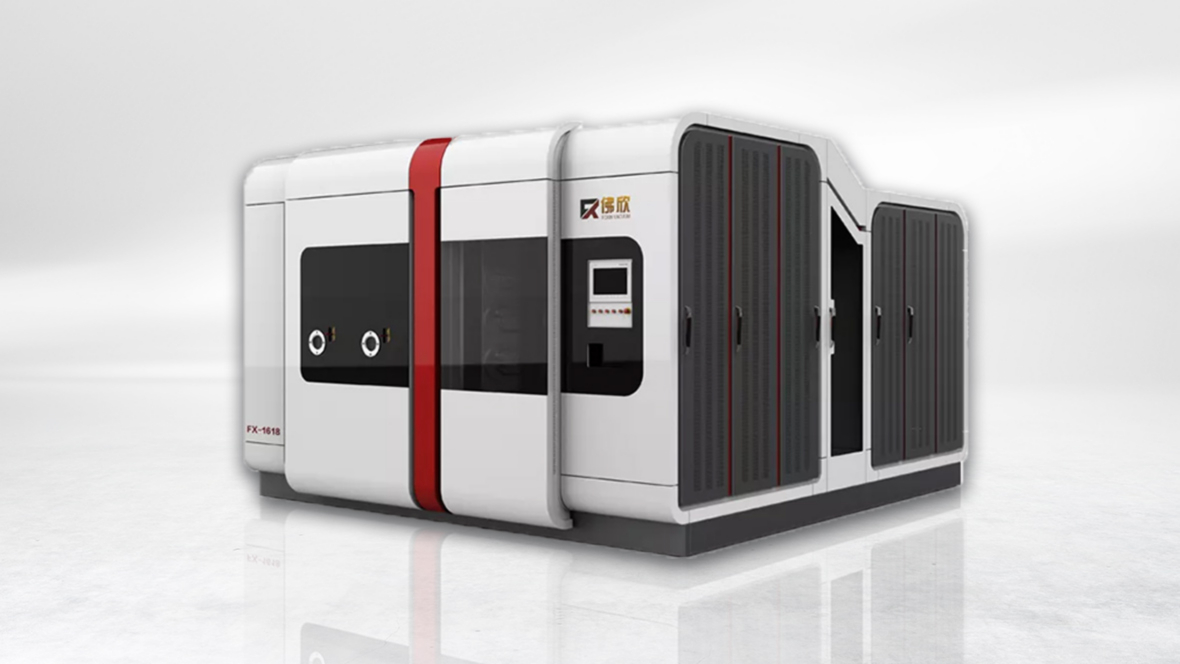

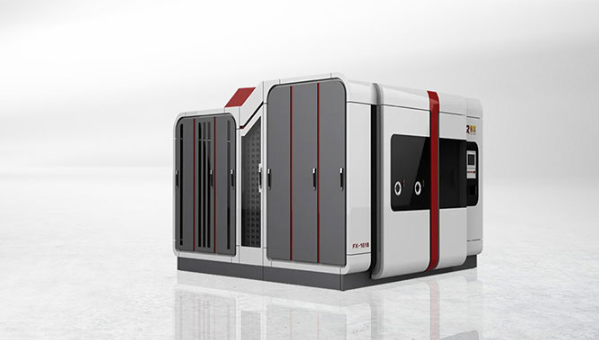

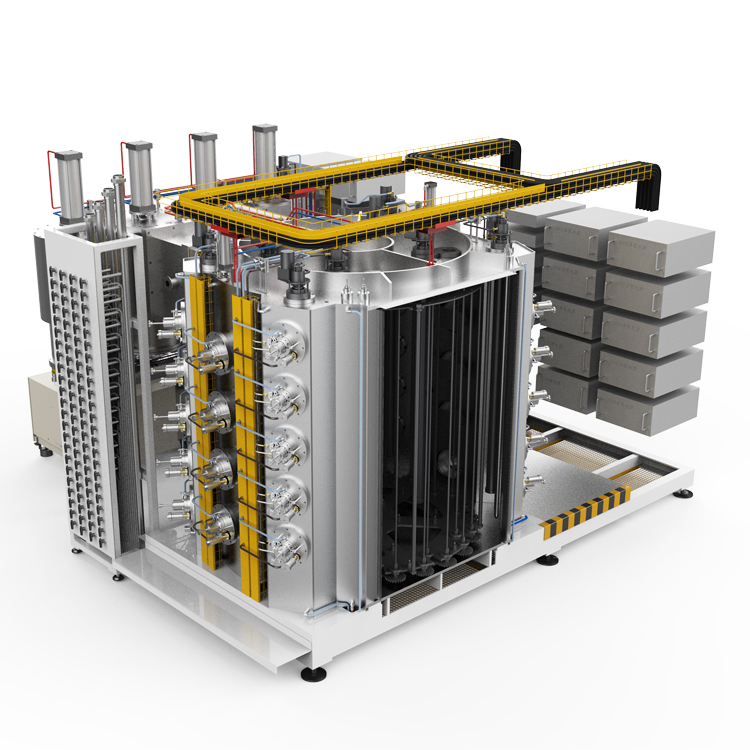

The Foxin Gold PVD Coating Equipment, a top-tier vacuum coating machine, is built to slap a tough, eye-catching gold coating onto all kinds of surfaces. This beast runs on physical vapor deposition (PVD method) tech, meaning it sprays gold material onto your base in a vacuum, layer by layer, for a smooth, even, and rock-solid finish. Whether you’re chasing a premium look or some serious durability, this PVD coating machine has got your back.

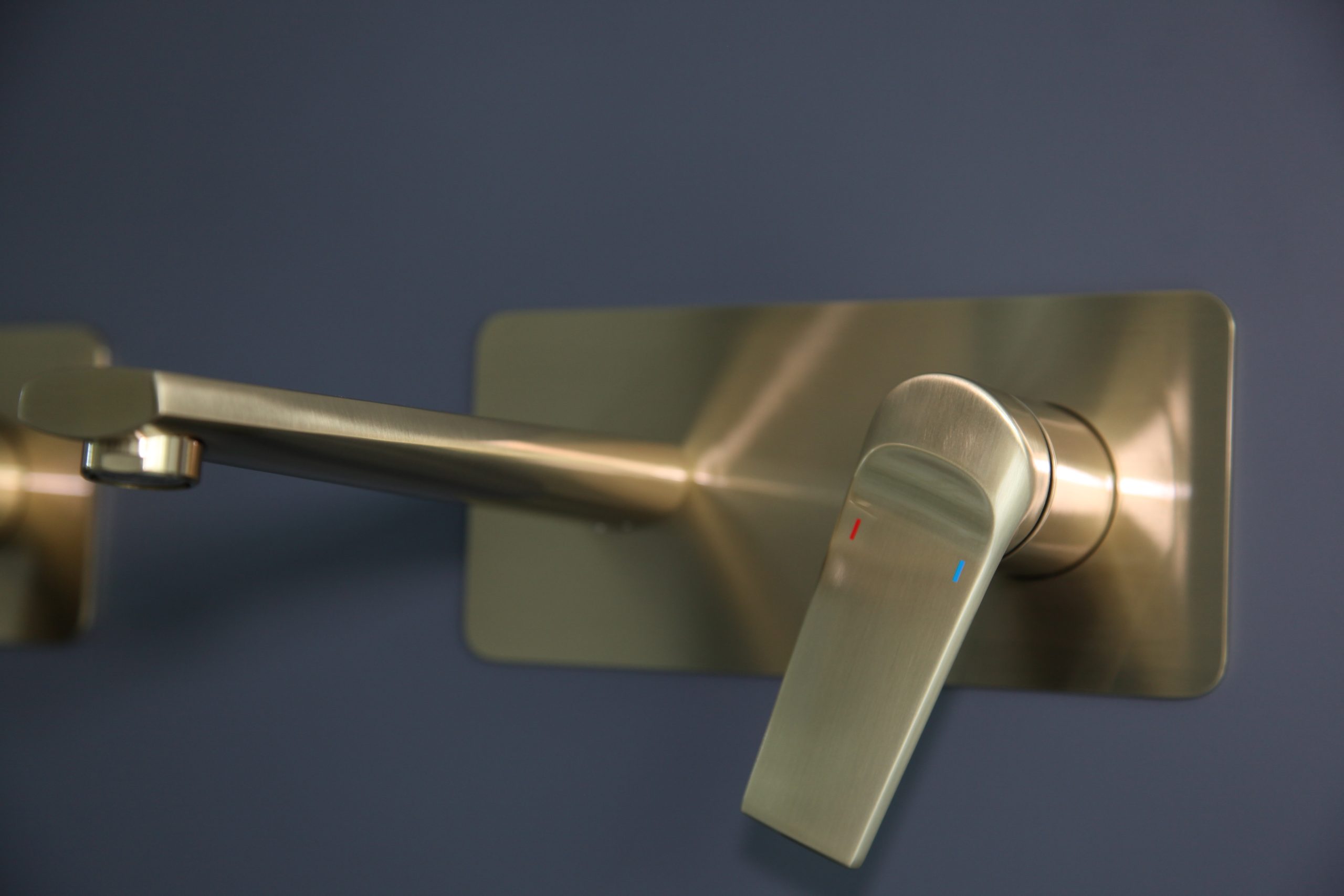

Compared to old-school electroplating machines, the Foxin PVD coating equipment blows them out of the water on eco-friendliness and quality. It nails stainless steel gold plating and high-end metal finishing like a pro, with scratch resistance and corrosion protection cranked to the max—perfect for jewelry, watches, or anything needing that gold-plated shine. Thanks to vacuum technology and a dialed-in PVD coating process, it locks in consistent thickness and natural color, delivering a finish that’s both tough and stunning.

This machine’s a total workhorse across industries, from whipping up gold PVD coatings for fancy decor to handling metal coating for hardcore tools. Want your product to look sharp and hold up under pressure? The Foxin Gold PVD Coating Equipment is your go-to partner—efficient, reliable, and a heavy hitter in modern coating equipment.

02 Gold Pvd Coating Features:

Advanced Control System: This bad boy comes loaded with a cutting-edge control system that gives you pinpoint precision over the PVD coating process. Say goodbye to guesswork—every run delivers consistent, top-notch gold PVD coatings that scream quality.

High Efficiency: Built for speed and smarts, this PVD coating machine is all about high-efficiency vibes. It cranks out fast processing times while sipping energy like a champ, keeping your costs low and your output high.

Multiple Color Options: Why settle for just gold? This vacuum coating machine dishes out a whole palette—think gold plating, rose gold, silver coating, black, and even custom shades. Whatever your vibe, it’s got the PVD finishing to match.

Automatic Operation: No babysitting required here. Designed for slick automatic operation, this coating equipment handles everything from loading to unloading your hardware. It’s like having a robot butler for your metal coating needs.

Fully Customizable: This PVD machine bends over backwards to fit your gig—whether it’s automotive, aerospace, or medical. Customize it to your specs and watch it nail stainless steel gold plating or any metal finishing job you throw its way.

03 Main Application

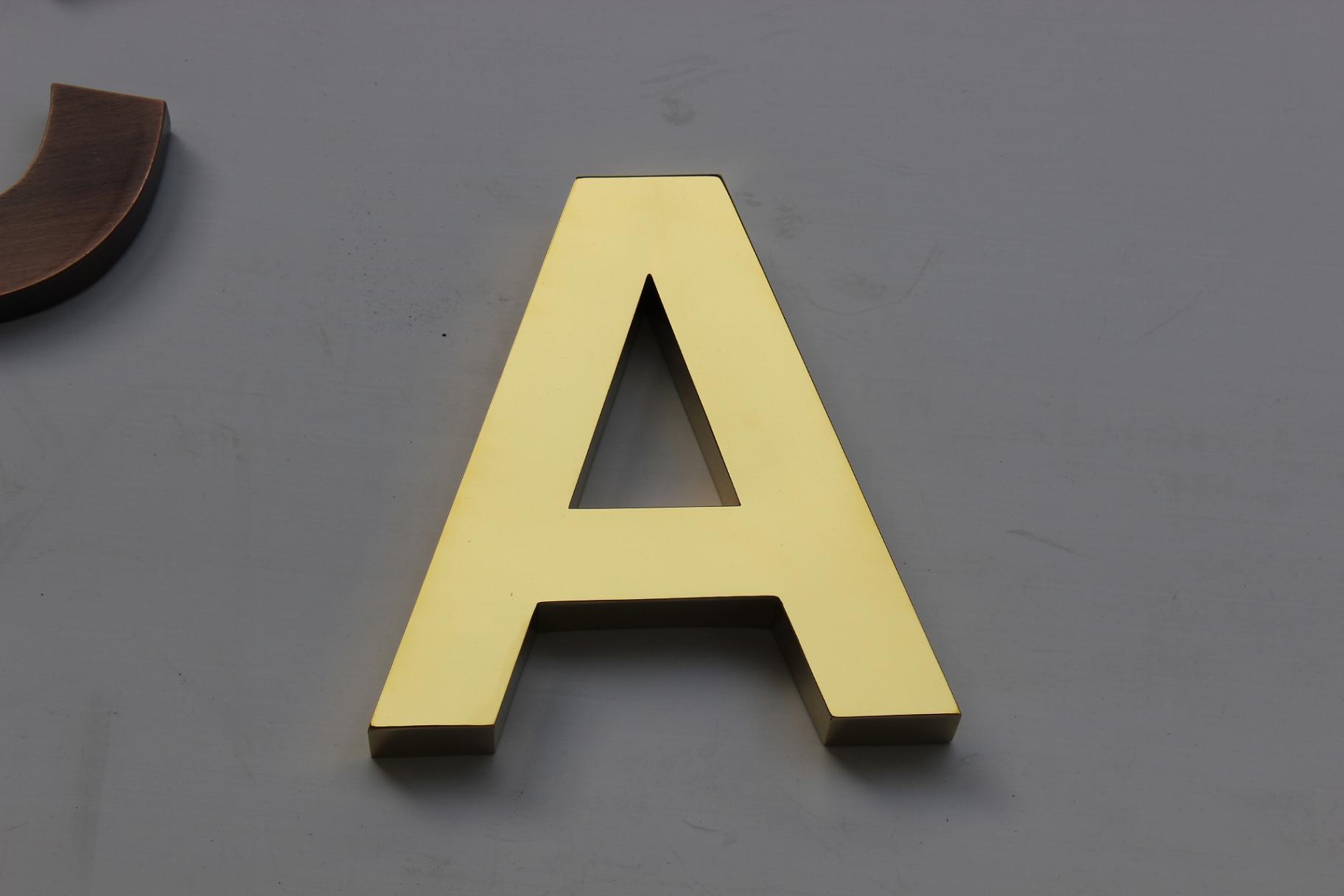

1. Decorative Coatings: This machine’s a game-changer for slapping stunning gold PVD coatings on jewelry, watches, and other bling-worthy items. It pumps out a high-quality, head-turning finish—perfect for gold plating that makes every piece pop.

2. Automotive Industry: Rev up your ride with this PVD coating machine. It’s built to lay down slick gold coatings on car parts like wheels, emblems, and trim, giving your vehicle that extra dose of style with a durable metal finishing touch.

3. Aerospace Industry: In the sky-high world of aerospace, this vacuum coating machine delivers. It coats aircraft parts—like turbine blades—with tough, corrosion-resistant gold PVD layers, keeping things running smooth and strong up there.

4. Medical Industry: For the medical field, this PVD machine brings the goods. It applies biocompatible, corrosion-proof gold coatings to implants and devices, ensuring top-tier performance with a metal coating that’s as reliable as it gets.

04 Download

Vacuum coating overview File name

05 Specifications

| Model | FOXIN-IP-0710 | FOXIN-IP-1012 | FOXIN-IP-1212 | FOXIN-IP-1412 | FOXIN-IP-1612 | FOXIN-IP-1813 |

| Chamber Size(mm) | Ф700×H1000 | Ф1000×H1200 | Ф1200×H1200 | Ф1400×H1200 | Ф1600×H1200 | Ф1800×H1300 |

| Industry | Watch industry, 3C industry, sanitary ware industry, jewelry industry, etc | |||||

| Product | Watch accessories, mobile phone accessories, glasses frames, clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic. | |||||

| Coating Film Type | Titanium, rose gold, champagne gold, Japanese gold, silver, colorful, sapphire orchid, rose red, black and so on | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 4set-6set | 6set-8set | 8set-10set | 10set-12set | 14set-16set | 16set-18set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 40KW/1set | 60KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 3set-4set | 3set-4set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | Argon, nitrogen, oxygen, acetylene, etc | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||