Gold pvd coating equipment manufacturer

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

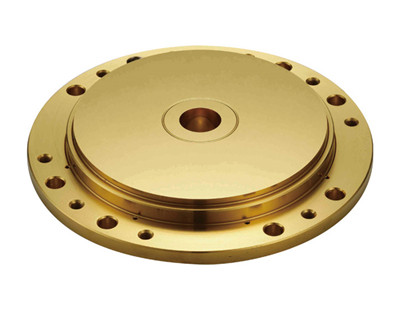

Looking to add a sleek, golden touch to your products? Our Gold PVD coating equipment is the perfect solution. As a trusted manufacturer, we craft PVD coating machines that use cutting-edge vacuum coating technology to apply a gorgeous layer of gold film to surfaces like metal, glass, plastic—you name it. Whether you’re jazzing up stainless steel gold plating or giving other materials a luxurious vibe with gold PVD coating, our gear gets the job done with style and precision.

The PVD coating process is straightforward yet impressive. Thanks to vacuum technology, our machines deliver a smooth, even gold coating that’s as tough as it is eye-catching. It’s ideal for everything from metal finishing to jewelry, offering a durable finish that elevates your work. Our PVD machines are built to keep things simple and efficient, so you can find the right coating equipment for your needs without breaking the bank—check out our competitive PVD coating machine price options and see for yourself!

02 Features

Vacuum Technology at Work: Our Gold PVD coating equipment uses a vacuum chamber to lay down a thin, gorgeous layer of gold onto your substrate. Think metal, glass, or plastic—quick and easy.

Built to Last: You’ll get a gold coating that’s uniform, tough, and ready to stand up to wear and corrosion. It’s perfect for long-lasting metal finishing.

Tailored to You: This PVD coating machine can be custom-made to handle all kinds of substrate sizes and shapes. Whatever your project calls for, we’ve got you covered.

Vivid Color Options: The gold PVD coating isn’t just one shade. It shifts beautifully depending on thickness, angle, and the material underneath, giving you a dynamic, eye-catching finish every time.

03 Main Application

1. Jewelry Industry: Our Gold PVD coating equipment takes jewelry to the next level—think dazzling rings, necklaces, and bracelets with a flawless gold coating that customers love.

2. Watch Industry: Perfect for coating watch cases, straps, and dials, this gear delivers a sharp gold PVD coating that’s both stylish and built to last.

3. Eyewear Industry: Give frames and lenses a premium feel with our PVD coating machines, blending fashion with a tough, protective finish.

4. Decorative & Functional Parts: Whether it’s eye-catching decor or components needing extra durability, our equipment lays down a gold coating that checks all the boxes.

5. Precision Coating Needs: With PVD vacuum coating technology, this machine shines in metal finishing, making it a go-to for industries wanting quality and consistency.

04 Download

Vacuum coating overview

05 Specifications

| Model | FOXIN-IP-0710 | FOXIN-IP-1012 | FOXIN-IP-1212 | FOXIN-IP-1412 | FOXIN-IP-1612 | FOXIN-IP-1813 |

| Chamber Size(mm) | Ф700×H1000 | Ф1000×H1200 | Ф1200×H1200 | Ф1400×H1200 | Ф1600×H1200 | Ф1800×H1300 |

| Industry | Watch industry, 3C industry, sanitary ware industry, jewelry industry, etc | |||||

| Product | Watch accessories, mobile phone accessories, glasses frames, clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic. | |||||

| Coating Film Type | Titanium, rose gold, champagne gold, Japanese gold, silver, colorful, sapphire orchid, rose red, black and so on | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 4set-6set | 6set-8set | 8set-10set | 10set-12set | 14set-16set | 16set-18set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 40KW/1set | 60KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 3set-4set | 3set-4set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 25~55m² | 25~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||