Pvd Vacuum Equipment Jewelry Plating Machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features

-

03 Main Application

-

04 Download

-

05 Specifications

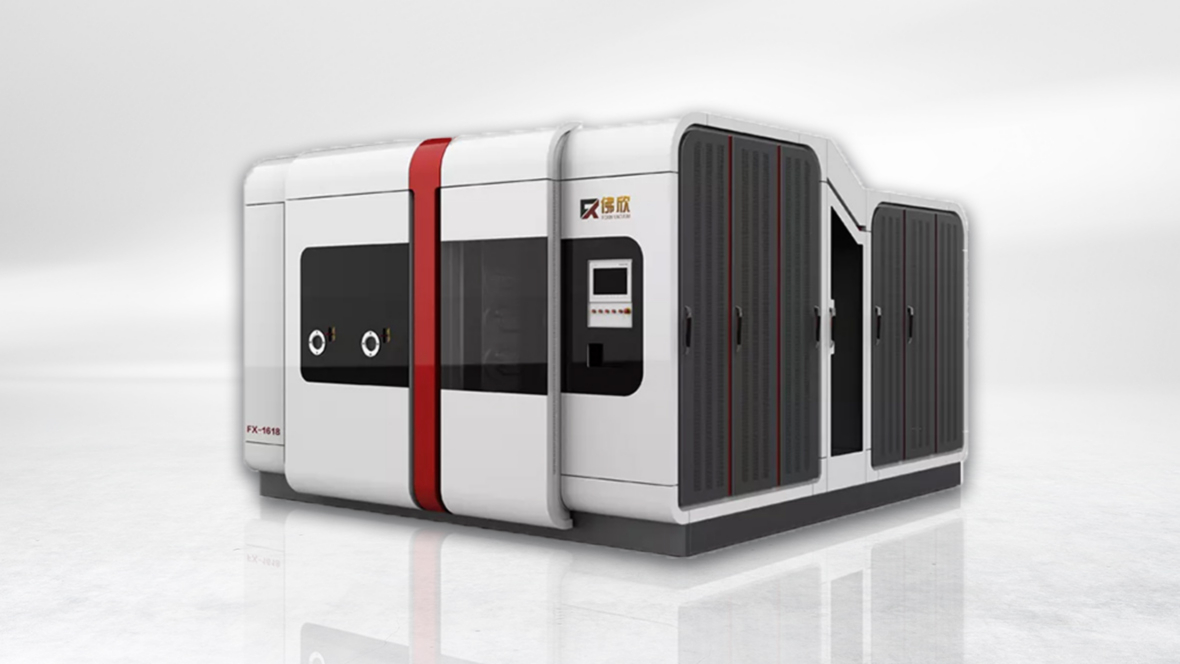

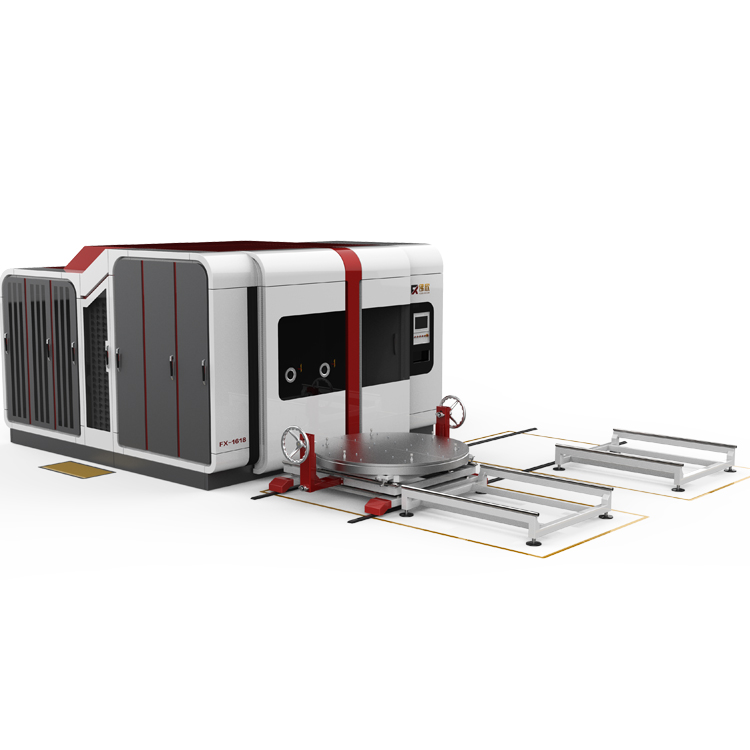

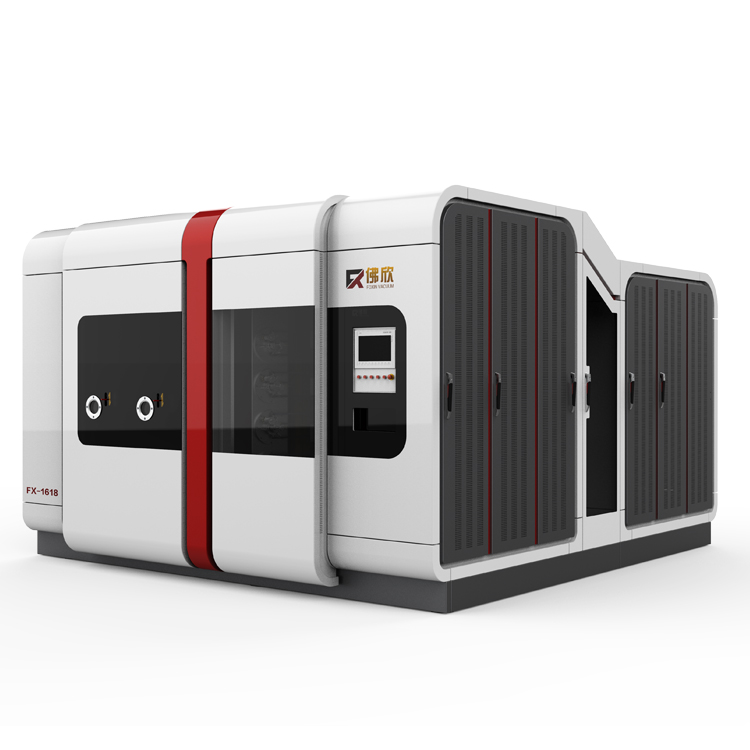

01 Overview

Our PVD Jewelry Plating Machine is all about making gold jewelry that grabs attention. This isn’t just another piece of coating equipment—it’s a reliable partner for crafting rings, necklaces, bracelets, earrings, and whatever else you’ve got in mind. Thanks to PVD coating and vacuum technology, it delivers results that look and feel top-notch.

What makes the Jewelry Gold Coating Equipment special is how it lays down a flawless layer of gold plating on every piece. The PVD coating process works its magic to give your jewelry a smooth, eye-catching shine that doesn’t fade. If you’re aiming for that perfect gold PVD coating finish, this machine has you covered.

It’s straightforward to use and built for anyone looking to step up their metal finishing. Whether you’re working on a custom order or cranking out a bigger batch, this equipment helps your creations stand out in the best way possible.

02 Features

Multi-arc Ion Source: This machine brings versatility to the table, letting you create a variety of PVD coatings with ease. From subtle to bold, it’s all about giving you options.

High Vacuum System: Equipped with a powerful vacuum technology setup, this system creates a low-pressure environment that’s just right for producing high-quality, consistent coating equipment results every time.

Substrate Holder: The sturdy substrate holder keeps everything in place, ensuring the PVD coating process deposits an even layer across your jewelry. No uneven spots—just smooth, reliable metal finishing.

Colors: Get ready to play with a spectrum of gold shades. This equipment can whip up stunning finishes like yellow gold, rose gold, and even black gold, all thanks to its top-notch gold PVD coating capabilities.

03 Main Application

1. Versatile Industry Use: This machine steps up across a range of fields, from aerospace and automotive to biomedical and tooling. Wherever PVD coating is needed, it’s ready to perform.

2. Industrial Applications: It’s a powerhouse for practical uses too. Think coating medical implants, aerospace parts, and electronic components with a durable layer of gold plating. The result? Enhanced durability and top-tier metal finishing that resists corrosion like a champ.

3. Research and Development: Perfect for the innovators out there, this equipment shines in R&D settings. It’s great for exploring the ins and outs of gold PVD coating, developing fresh gold plating techniques, and testing how different PVD coatings hold up on various materials.

04 Download

Vacuum coating overview

05 Specifications

| Model | FOXIN-IP-0710 | FOXIN-IP-1012 | FOXIN-IP-1212 | FOXIN-IP-1412 | FOXIN-IP-1612 | FOXIN-IP-1813 |

| Chamber Size(mm) | Ф700×H1000 | Ф1000×H1200 | Ф1200×H1200 | Ф1400×H1200 | Ф1600×H1200 | Ф1800×H1300 |

| Industry | Watch industry, 3C industry, sanitary ware industry, jewelry industry, etc | |||||

| Product | Watch accessories, mobile phone accessories, glasses frames, clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic. | |||||

| Coating Film Type | Titanium | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 4set-6set | 6set-8set | 8set-10set | 10set-12set | 14set-16set | 16set-18set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW | 20KW | 20KW | 30KW/1set | 40KW/1set | 60KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 3set-4set | 3set-4set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | Argon, nitrogen, oxygen, acetylene, etc | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||