Gold Pvd Coating Equipment

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Gold Pvd Coating Features:

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

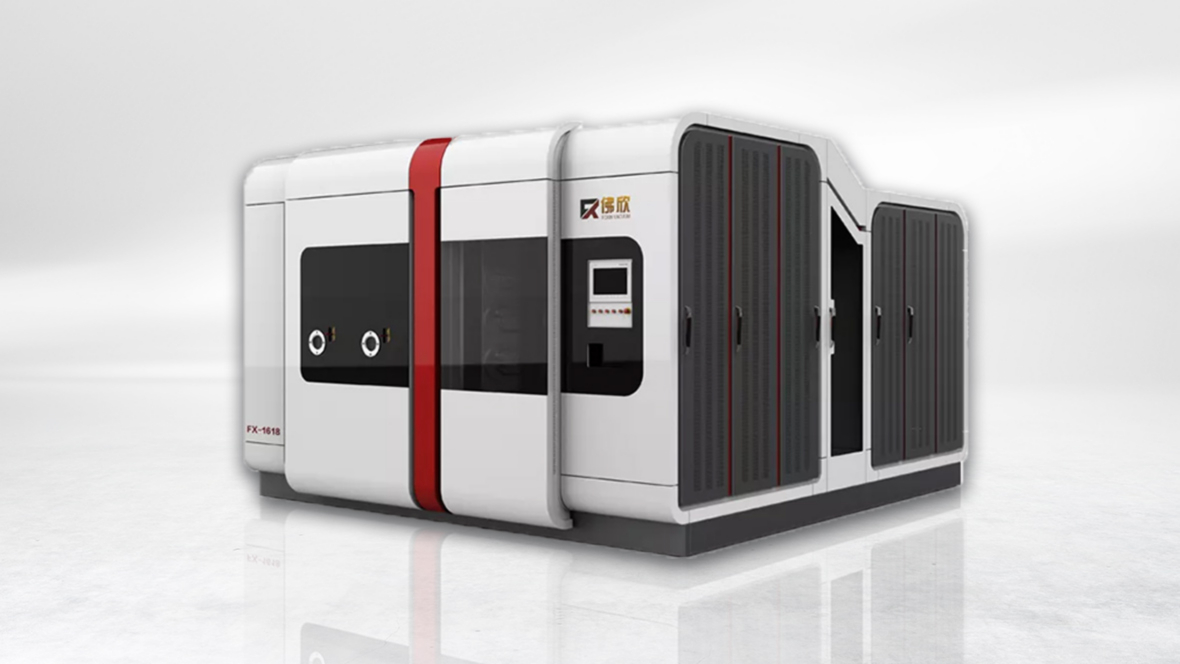

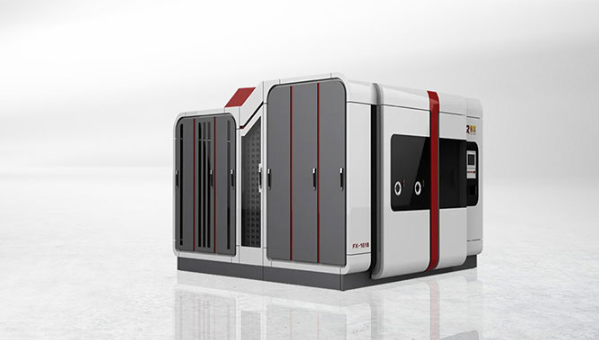

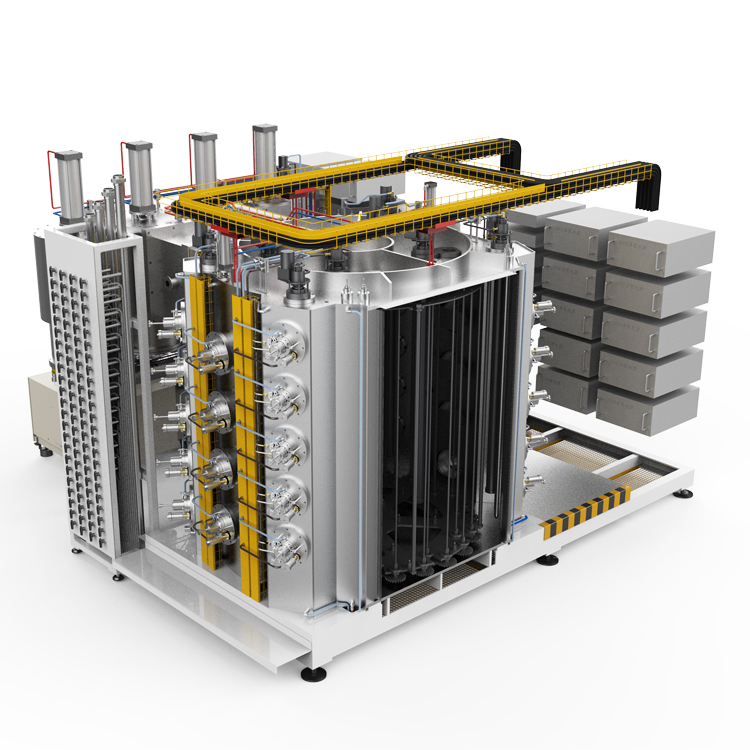

The Foxin Gold PVD Coating Equipment or PVD Vacuum Coating Machine is a specialize machine designe for applying a thin, durable layer of gold coating onto various types of surfaces. Below are some details on the purpose, features, and applications of this equipment:

Purpose: The primary purpose of the Foxin Gold PVD Coating Equipment is to provide a durable and attractive gold coating to a variety of surfaces. The machine uses a physical vapor deposition (PVD) process to apply the gold coating, which provides a uniform and high-quality finish that is resistant to scratches and wear.

02 Gold Pvd Coating Features:

Advanced Control System: The machine is equippe with an advanced control system that allows for precise control over the PVD coating process, ensuring consistent and high-quality results.

High Efficiency: The machine is designe for high-efficiency operation, with a fast processing speed and low energy consumption.

Multiple Colors: The machine offers a variety of color options for PVD coatings, including gold, rose gold, silver, black, and other custom colors.

Automatic Operation: The machine is designe for automatic operation, with features such as automatic loading and unloading of the hardware.

Customizable: The machine can be customize to meet the specific needs of different industries, such as automotive, aerospace, and medical.

03 Main Application

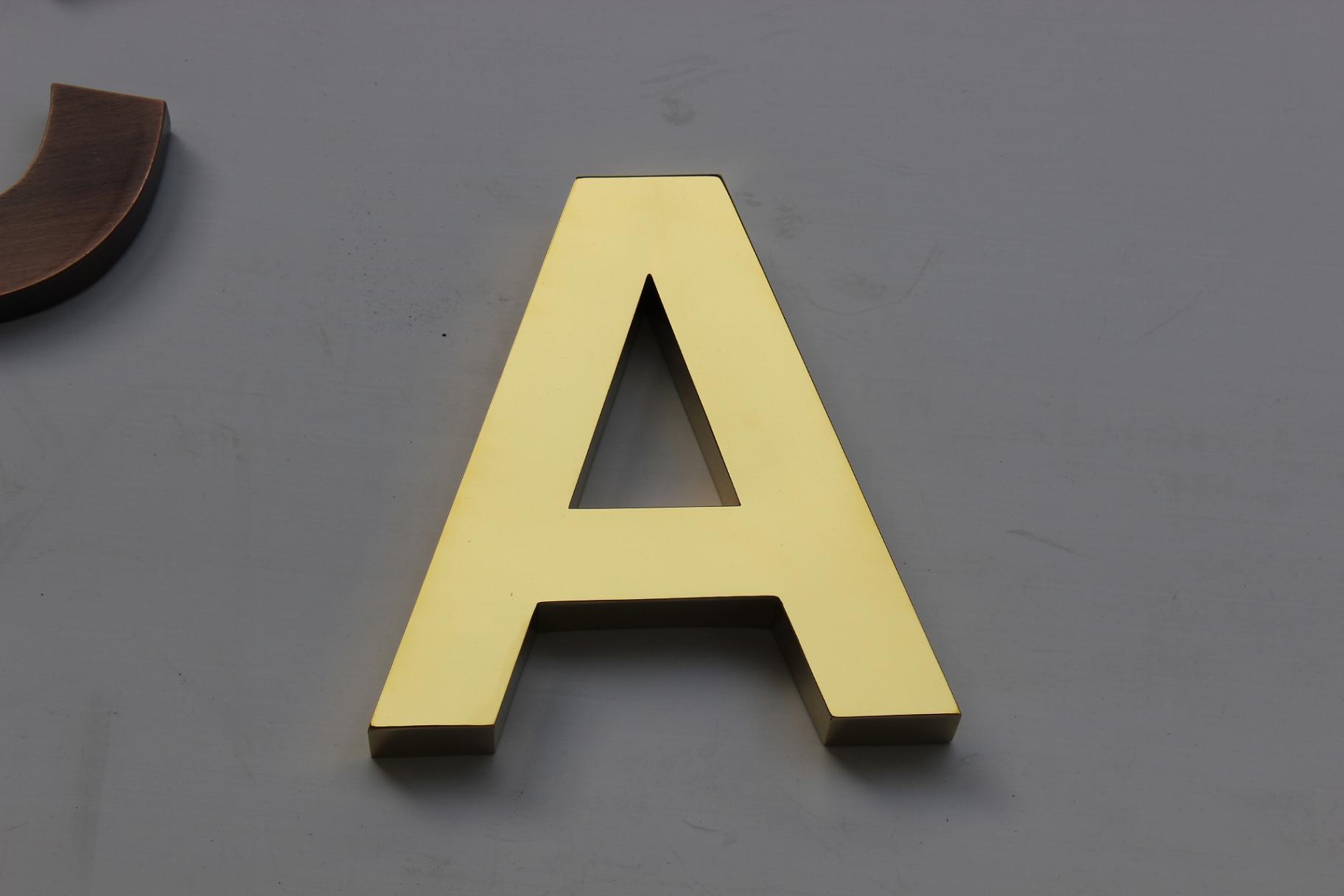

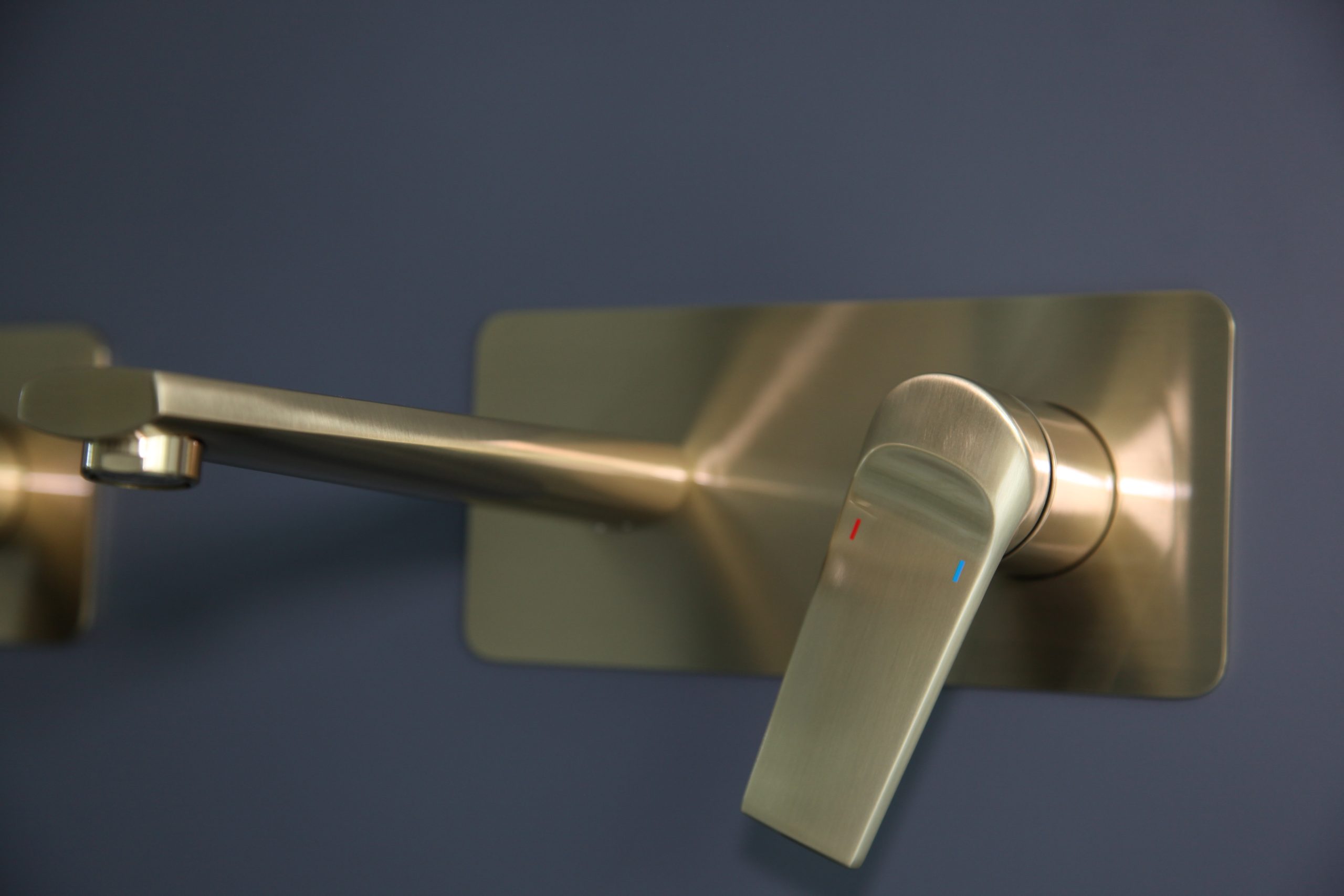

1、Decorative Coatings: The machine can be use to apply gold coatings onto jewelry, watches, and other decorative items, providing a high-quality and attractive finish.

2、Automotive Industry: The machine can be use to apply gold coatings onto automotive parts, such as wheels, emblems, and trim, enhancing the aesthetic appeal of the vehicle.

3、Aerospace Industry: The machine can be use to apply gold coatings onto aircraft parts, such as turbine blades, providing a durable and corrosion-resistant finish.

4、Medical Industry: The machine can be use to apply gold coatings onto medical implants and devices, providing a biocompatible and corrosion-resistant finish.

04 Download

Vacuum coating overview File name

05 Specifications

| Model | FOXIN-IP-0710 | FOXIN-IP-1012 | FOXIN-IP-1212 | FOXIN-IP-1412 | FOXIN-IP-1612 | FOXIN-IP-1813 |

| Chamber Size(mm) | Ф700×H1000 | Ф1000×H1200 | Ф1200×H1200 | Ф1400×H1200 | Ф1600×H1200 | Ф1800×H1300 |

| Industry | Watch industry, 3C industry, sanitary ware industry, jewelry industry, etc | |||||

| Product | Watch accessories, mobile phone accessories, glasses frames, clothing, lighting, sanitary ware, hardware bags, glass, ceramics, and plastic. | |||||

| Coating Film Type | Titanium, rose gold, champagne gold, Japanese gold, silver, colorful, sapphire orchid, rose red, black and so on | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 4set-6set | 6set-8set | 8set-10set | 10set-12set | 14set-16set | 16set-18set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 40KW/1set | 60KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 3set-4set | 3set-4set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | Argon, nitrogen, oxygen, acetylene, etc | ||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||