Ceramic Tiles Intermediate Frequency Multifunction

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features of the Machine Include

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

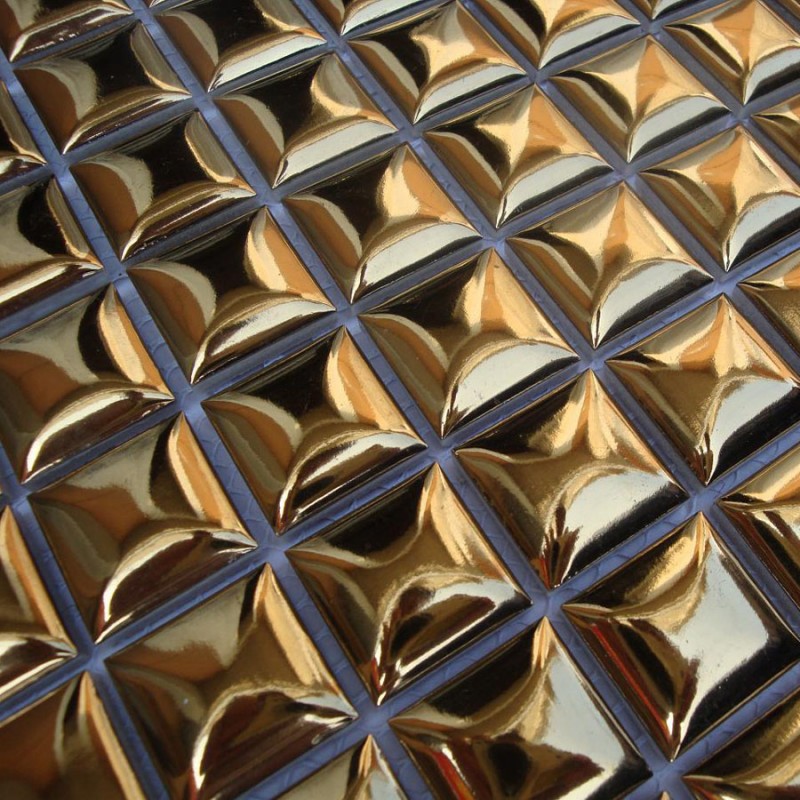

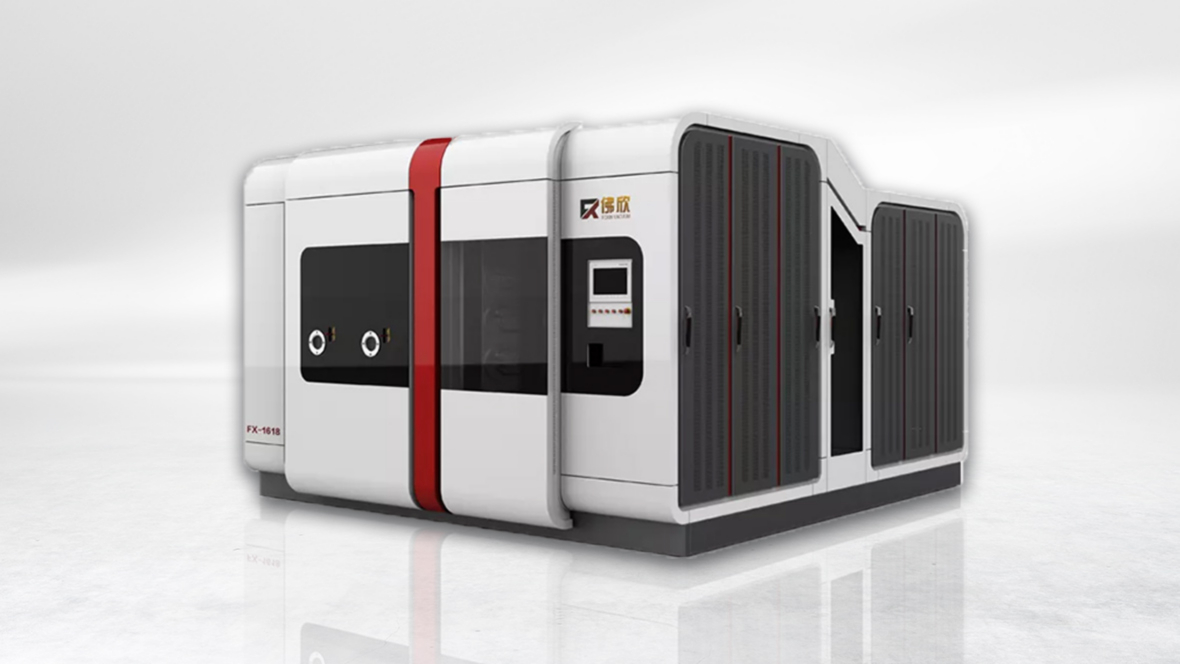

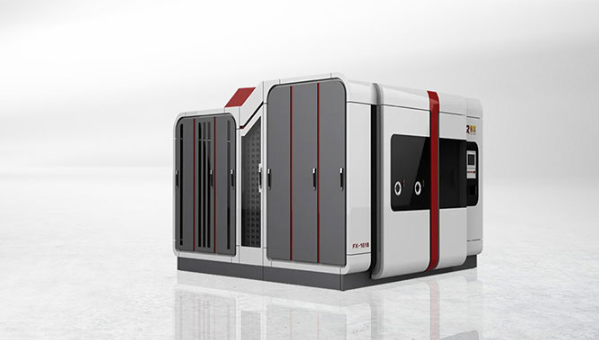

The Stainless Steel Sheet Gold PVD Coating Machine is your ticket to turning plain stainless steel into something special. Picture this: a machine that uses vacuum technology to add a brilliant gold PVD coating, giving your steel sheets a look that’s both classy and tough.

So, how does it pull this off? It’s all about Physical Vapor Deposition (PVD)—a process that lays down a thin layer of gold onto the steel. You end up with PVD coated stainless steel that’s got the strength to handle wear and tear, plus the sleek shine of gold plating. It’s the kind of finish that works just as well for a high-end design as it does for something practical you use every day.

What sets this PVD coating machine apart is how easy it makes the whole process. With magnetron sputtering, you’re getting consistent, top-notch results without any guesswork. It’s designed for people who need equipment that’s fast, dependable, and doesn’t overcomplicate things. Curious about the PVD coating process or wondering what the PVD coating machine price looks like? This piece of coating machinery brings premium quality within reach, with no hassle involved.

02 Features of the Machine Include

Automatic Operation: This PVD coating machine takes care of everything on its own. No need to hover over it—just set it up and watch it crank out your gold PVD coating with less effort and more speed.

Multifunctionality: It’s like having a whole crew in one machine. From prepping the steel to applying that sleek PVD coating process, it handles multiple steps so you can keep things moving without extra gear.

High Precision: You want a finish that looks perfect and lasts? This machine’s got it covered. It turns out PVD coated stainless steel with a sharp, reliable gold plating look every single time.

Energy-Efficient: Using vacuum technology and magnetron sputtering, it’s smart about power. You get awesome results without racking up a huge energy bill—practical and budget-friendly all the way.

03 Main Application

1. Ceramic Tile Production: This PVD coating machine shines when it comes to making ceramic tiles. It’s built to handle the PVD coating process, giving tiles a durable, gold PVD coating that stands out and holds up.

2. Other Industries: Beyond tiles, this versatile piece of coating machinery fits right into other fields too. Need material prep, pressing, or a slick gold plating finish on PVD coated stainless steel? It’s got the flexibility to tackle those jobs with ease.

04 Download

PVD-Vacuum multi-arc ion coating

05 Specifications

| Model | TG-1418 | TG-1620 | TG-1820 | TG-2020 | TG-2023 | TG-2030 | |

| Chamber Size(mm) | Ф1400×H1800mm | Ф1600×H2000mm | Ф1800×H2000mm | Ф2000×H2000mm | Ф2000×H2300mm | Ф2000×H3000mm | |

| Application | Hardware industry, sanitary appliance industry | decoration industry, household appliances industry | Faucet, stair handrail, household appliances | LOGO signs, stainless steel frame | stainless steel parts and plate, etc | ||

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver | Colorful | Sapphire orchid | Rose red, black and so on |

| Vacuum Chamber | equip with pumping system and water cooling system | Vertical door, hanging or horizontal cart structure | |||||

| Vacuum System | Sustaining Pump +Mechanical Pump + Roots Pump + Diffusion Pump | Molecule Pump(specific model according to customers' requirements) | |||||

| Vacuum | 1 set pirani | 1 set cold cathode | 1 set diaphragm gauge | ||||

| Supply Type | DC power | MF power, | pulse power(bias power, arc power) | ||||

| Ultimate | 1.0-6.0x10-4Pa | Non-loading cooling | |||||

| Arc Source | 16-24 set | 16-24 set | 18-26 set | 18-26 set | 22-28 set | 22-28 set | |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | |

| Bias Power | 40KW/1 set | 40KW/1 set | 40KW/1 set | 50KW/1 set | 50KW/1 set | 60KW/1 set | |

| Magnetron Power Supply | 1-2 set | 1-2 set | 2-3 set | 2-3 set | - - | - - | |

| Rotation | Mult-axis planetary with frequency control | Can be controlled and adiustec | |||||

| Baking | Normal temperature ~300C can be controlled and adjusted(PID temperature control) | ||||||

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | |||||

| Cooling Method | Water cooling circulation | equip with industrial cooling tower | industrial water chiller(refrigerating machine) | cryogenic system(customers provide) | |||

| Controlling | Manual | half-auto, auto | touch screen operation | PLC or computer controlled | |||

| Supply Index | Air Pressure 0.5-0.8MPa | Water Temperature<25C | Water Pressure>0.2MPa | ||||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happensand carry out related protect solution and electric interlock. | ||||||

| Total Power | 100~125KW | 125~145KW | 145~165KW | 165~185KW | 185~200KW | 200KW | |

| Output | Voltage 220V,Frequency 50Hz(equip as customers' national electricity standard) | ||||||

| Occupation | 15~50㎡ | 15~50㎡ | 25~55㎡ | 25~55㎡ | 35~55㎡ | 35~55㎡ | |

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | ||||||