Pvd Ceramic Tiles Sputtering Coating Machine For Sale

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Working principle:

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

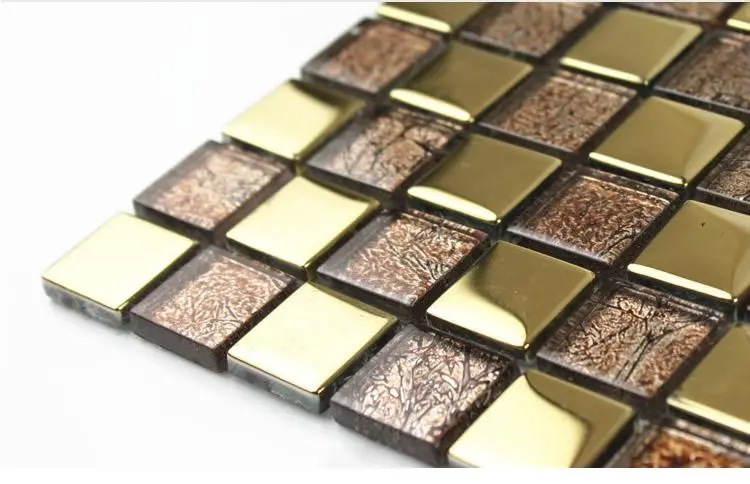

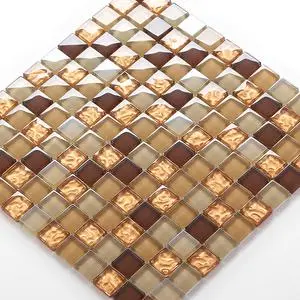

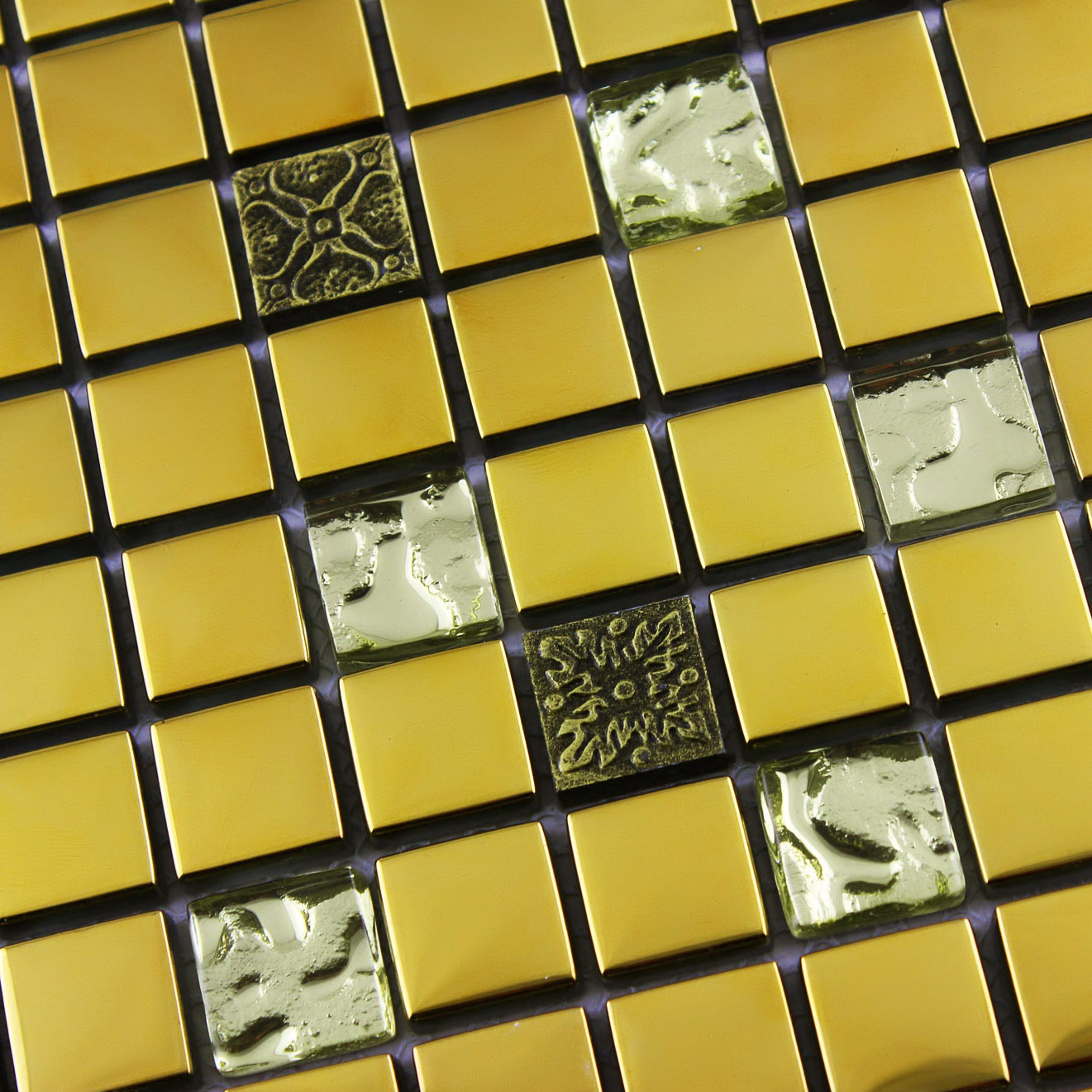

PVD tile sputtering coating machine for sale. It is done using a physical vapor deposition process on a tile coated with a thin film. Coatings can provide decorative properties, such as metallic or matte finishes.

02 Working principle:

Loading: Ceramic tiles are loaded onto a substrate holder inside a vacuum chamber.

Vacuum: The chamber is evacuated to remove any contaminants that could interfere with the coating process.

Sputtering: The coating material, typically a metal, is introduced into the chamber as a vapor. A high-energy plasma ionizes the vapor and accelerates ions toward the ceramic tile surface.

Deposition: When ions strike the surface of a ceramic tile, they deposit a thin film of coating material. The thickness of the coating can be controlled by adjusting sputtering process parameters such as power level and gas pressure.

Finishing: After the coating process is complete, the chamber is vented and the ceramic tiles are unloaded.

03 Main Application

1、Decorative coating: Deposit various decorative coatings on the tile. Create unique and visually appealing patterns and designs, and enhance the durability of the tiles.

2、Wear-resistant coating: Deposit a wear-resistant coating on the tile to help extend its service life.

3、Anticorrosive coatings: Anticorrosive coatings on the tiles help protect the tiles from damage caused by harsh environments.

04 Download

Vacuum coating overview

05 Specifications

| Model | TG-1418 | TG-1620 | TG-1820 | TG-2020 | TG-2023 | TG-2030 |

| Chamber Size(mm) | Ф1400×H1800mm | Ф1600×H2000mm | Ф1800×H2000mm | Ф2000×H2000mm | Ф2000×H2300mm | Ф2000×H3000mm |

| Application | Hardware industry, sanitary appliance industry | decoration industry, household appliances industry | Faucet, stair handrail, household appliances | LOGO signs, stainless steel frame | stainless steel parts and plate, etc | |

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver/Colorful | Sapphire orchid | Rose red, black and so on |

| Vacuum Chamber | equip with pumping system and water cooling system | Vertical door, hanging or horizontal cart structure | ||||

| Vacuum System | Sustaining Pump +Mechanical Pump + Roots Pump + Diffusion Pump | Molecule Pump(specific model according to customers' requirements) | ||||

| Vacuum | 1 set pirani | 1 set cold cathode | 1 set diaphragm gauge | |||

| Supply Type | DC power | MF power, | pulse power(bias power, arc power) | |||

| Ultimate | 1.0-6.0x10-4Pa | Non-loading cooling | ||||

| Arc Source | 16-24 set | 16-24 set | 18-26 set | 18-26 set | 22-28 set | 22-28 set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power | 40KW/1 set | 40KW/1 set | 40KW/1 set | 50KW/1 set | 50KW/1 set | 60KW/1 set |

| Magnetron Power Supply | 1-2 set | 1-2 set | 2-3 set | 2-3 set | - - | - - |

| Rotation | Mult-axis planetary with frequency control | Can be controlled and adiustec | ||||

| Baking | Normal temperature ~300C can be controlled and adjusted(PID temperature control) | |||||

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | ||||

| Cooling Method | Water cooling circulation | equip with industrial cooling tower | industrial water chiller(refrigerating machine) | cryogenic system(customers provide) | ||

| Controlling | Manual | half-auto, auto | touch screen operation | PLC or computer controlled | ||

| Supply Index | Air Pressure 0.5-0.8MPa | Water Temperature<25C | Water Pressure>0.2MPa | |||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happensand carry out related protect solution and electric interlock. | |||||

| Total Power | 100~125KW | 125~145KW | 145~165KW | 165~185KW | 185~200KW | 200KW |

| Output | Voltage 220V,Frequency 50Hz(equip as customers' national electricity standard) | |||||

| Occupation | 15~50㎡ | 15~50㎡ | 25~55㎡ | 25~55㎡ | 35~55㎡ | 35~55㎡ |

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | |||||