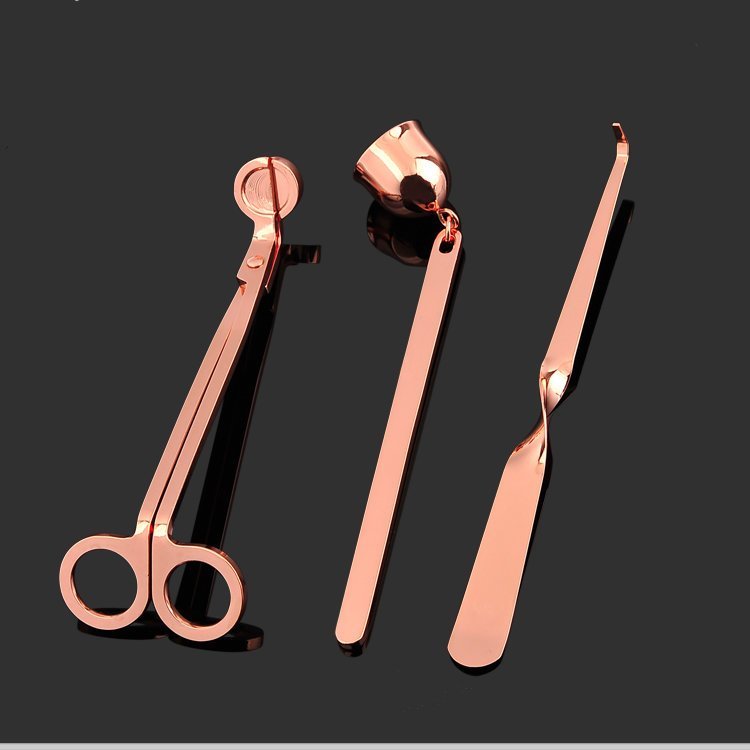

Stainless Steel Metal Parts Steel Titanium Pvd Deposit Machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features

-

03 Main Application

-

04 Download

-

05 Specifications

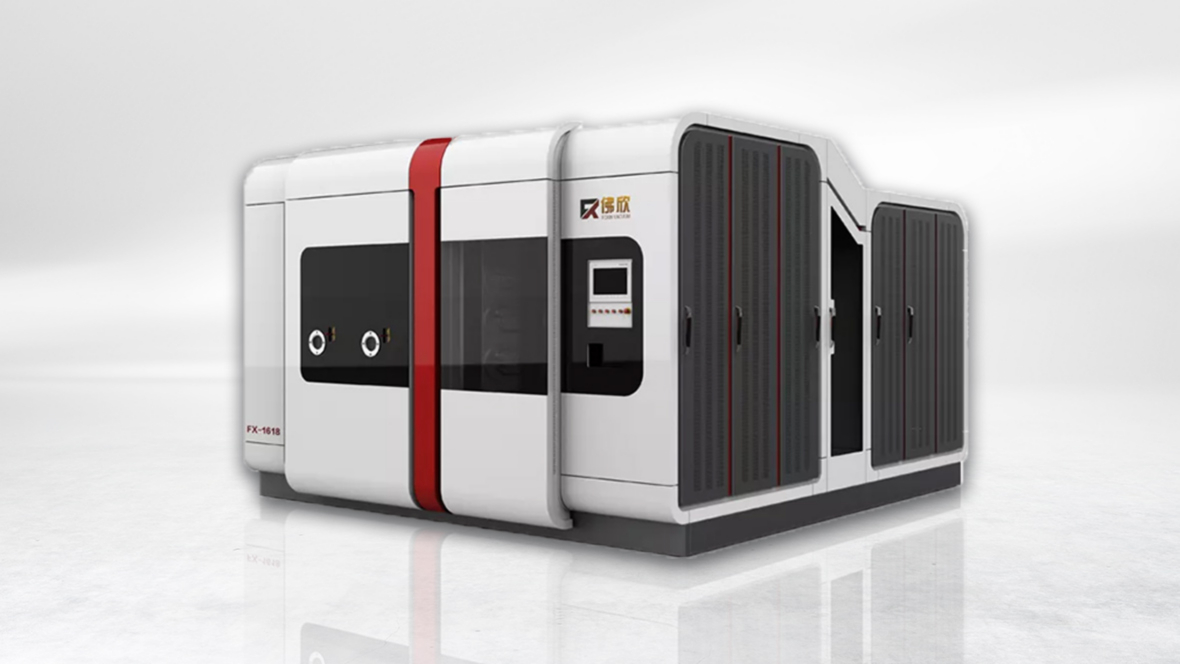

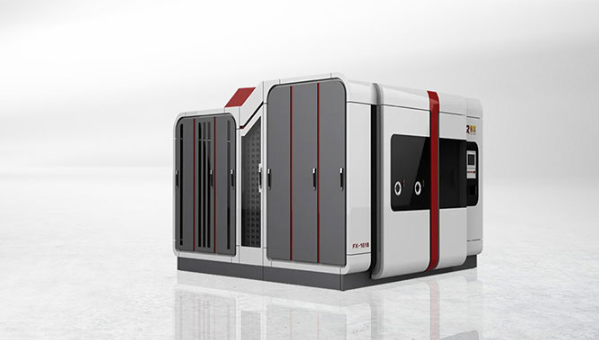

01 Overview

The Stainless Steel Sheet Gold PVD Coating Machine is about seriously upgrading stainless steel. Think of it as coating equipment that doesn’t just do the job—it does it well. With a proven PVD coating process, this machine layers on a gold PVD finish that’s as durable as good-looking. It uses vacuum technology to apply a thin titanium film, turning plain stainless steel into something ready for whatever you throw at it.

Why’s that a win? Your steel ends up tougher, shrugs off corrosion like it’s no big deal, and gets a sharp gold coating that catches the eye. Whether making parts that need to last or creating something with a little extra style, you’ll get PVD-coated stainless steel that’s up to the task. It’s metal finishing that feels practical and polished—built for real use, not just for show.

02 Features

Vacuum Chamber: This machine comes with a sturdy vacuum chamber where the magic happens. It’s where we load the stainless steel parts to get that flawless PVD coating underway.

Plasma Source: Equipped with a powerful plasma source, this setup generates high-energy plasma to get the job done. It ionizes titanium atoms and deposits them smoothly onto your parts for a perfect gold PVD finish.

Power Supply: A reliable power supply keeps everything running strong. It feeds the plasma source and titanium target with just the right amount of juice to make the PVD coating process hum along.

Cooling System: The built-in cooling system has your back during the PVD process. It keeps the parts from overheating, ensuring they come out with a top-notch metal coating every time.

Target Material: The target material here is pure titanium, ready to deliver. It produces a steady stream of titanium atoms that get ionized and layered onto your parts, creating that standout PVD-coated stainless steel look.

03 Main Application

1. Stainless Steel in Action: Materials like stainless steel, steel, and titanium are go-to choices across all kinds of industries. We’re talking automotive, aerospace, medical, and even everyday consumer goods—anywhere you need reliable, high-quality metal finishing.

2. Boosting Performance: The PVD coating process (that’s Physical Vapor Deposition, by the way) is a proven way to add thin films that make a big difference. It ramps up wear resistance, fights off corrosion, and gives your parts a sharp gold PVD look that’s tough to beat.

04 Download

PVD-Vacuum multi-arc ion coating

05 Specifications

| Model | TG-1418 | TG-1620 | TG-1820 | TG-2020 | TG-2023 | TG-2030 | |

| Chamber Size(mm) | Ф1400×H1800mm | Ф1600×H2000mm | Ф1800×H2000mm | Ф2000×H2000mm | Ф2000×H2300mm | Ф2000×H3000mm | |

| Application | Hardware industry, sanitary appliance industry, decoration industry, household appliances industry | Faucet, stair handrail, household appliances, LOGO signs, stainless steel frame, stainless steel parts and plate, etc | |||||

| Coating Film | Ti-Gold, Rose Gold, Champagne Gold, Japanese Gold, Bright Silver, Rainbow, Jewelry Blue, Rose Red, Black, etc. | ||||||

| Vacuum Chamber | Vertical door, hanging or horizontal cart structure, equip with pumping system and water cooling system | ||||||

| Vacuum System | Sustaining Pump +Mechanical Pump + Roots Pump + Diffusion Pump | or Molecule Pump(specific model according to customers' requirements) | |||||

| Vacuum | 1 set pirani, 1 set cold cathode, 1 set diaphragm gauge | ||||||

| Supply Type | DC power, MF power, pulse power(bias power, arc power) | ||||||

| Ultimate | 1.0-6.0x10-4Pa,Non-loading cooling | ||||||

| Arc Source | 16-24 set | 16-24 set | 18-26 set | 18-26 set | 22-28 set | 22-32 set | |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | |

| Bias Power | 40KW/1 set | 40KW/1 set | 40KW/1 set | 50KW/1 set | 50KW/1 set | 60KW/1 set | |

| Magnetron Power Supply | 1-2 set | 1-2 set | 2-3 set | 2-3 set | --- | --- | |

| Rotation | Mult-axis planetary with frequency controllcan be controlled and adiustec) | ||||||

| Baking | Normal temperature ~300C can be controlled and adjusted(PID temperature control) | ||||||

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver | Colorful | Sapphire orchid | Rose red, black and so on |

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | |||||

| Cooling Method | Water cooling circulation, equip with industrial cooling tower or industrial water chiller(refrigerating machine)or cryogenic system.(customers provide) | ||||||

| Controlling | Manual, half-auto, auto, touch screen operation, PLC or computer controlled | ||||||

| Supply Index | Air Pressure 0.5-0.8MPa, Water Temperature<25C,Water Pressure>0.2MPa | ||||||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happens | and carry out related protect solution and electric interlock. | |||||

| Total Power | 100~125KW | 125~145KW | 145~165KW | 165~185KW | 185~200KW | 200KW | |

| Occupation | 15~50m2 | 15~50m2 | 25~55m2 | 25~55m2 | 35~55m2 | 35~55m2 | |

| Output | Voltage 220V,Frequency 50Hz(equip as customers' national electricity standard) | ||||||

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | ||||||