High-Performance Pvd Vacuum Coating Machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Features

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

02 Features

Multi-Functional Coating: This PVD machine is like a toolbox for coatings. It can slap on tough layers like titanium nitride, chromium nitride, or even a slick gold PVD finish—perfect for giving stainless steel plates the exact vibe you’re going for.

Uniform Coating Thickness: Got a huge stainless steel plate or tiny accessories? No problem. This thing spreads an even PVD coating every time, so your parts look good and work great, edge to edge.

Energy Efficiency: With its clever vacuum technology and a plasma source that doesn’t guzzle power, this PVD vacuum coating machine keeps your energy bills low while still pumping out top-quality results.

Automation: It’s hands-off and hassle-free. The machine runs the PVD coating process on its own, delivering steady metal finishing without you having to babysit it—less work, more payoff.

Environmentally Friendly: This coating equipment keeps things clean. No smoke, no mess—just a smooth PVD process that’s kind to the planet and still gets the job done right.

03 Main Application

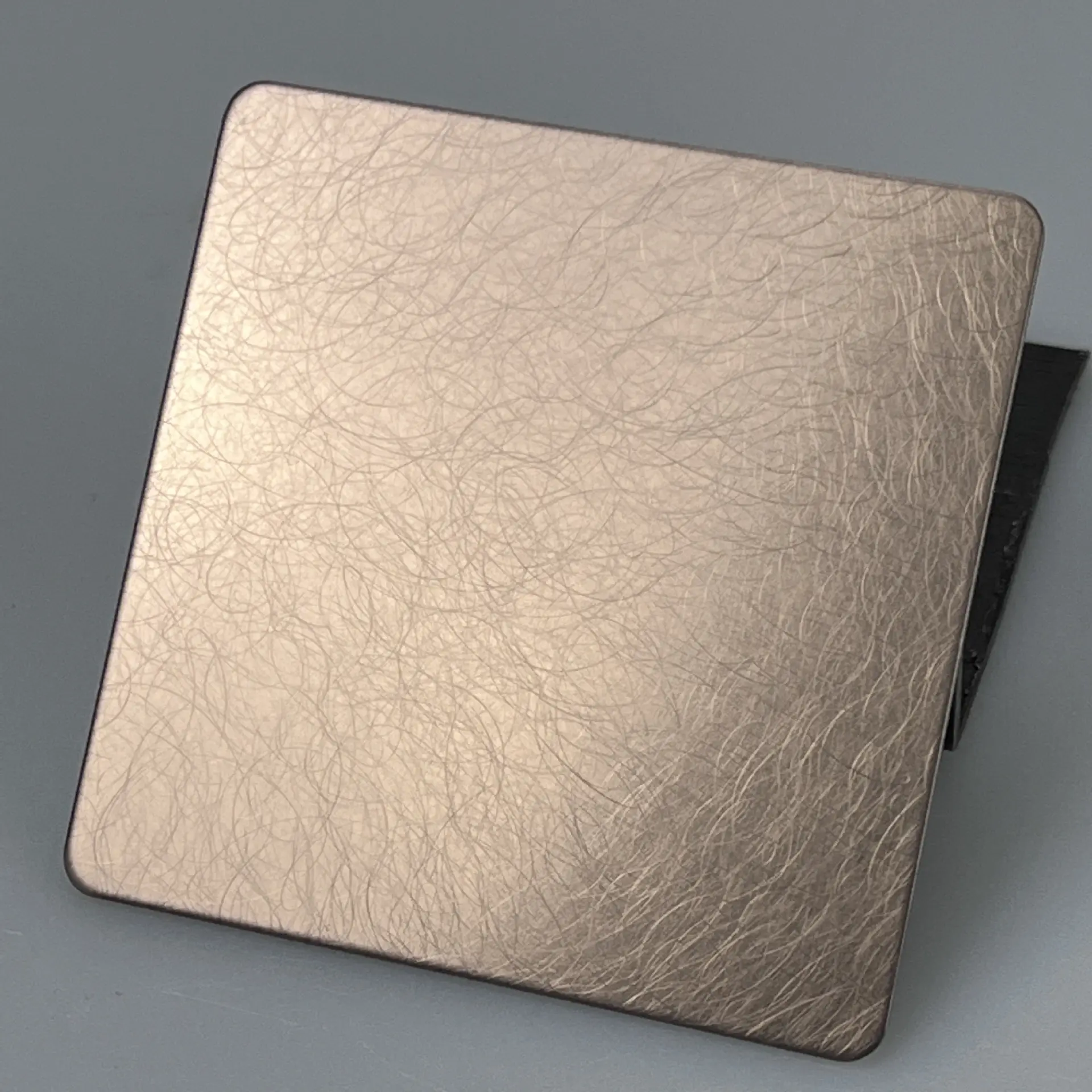

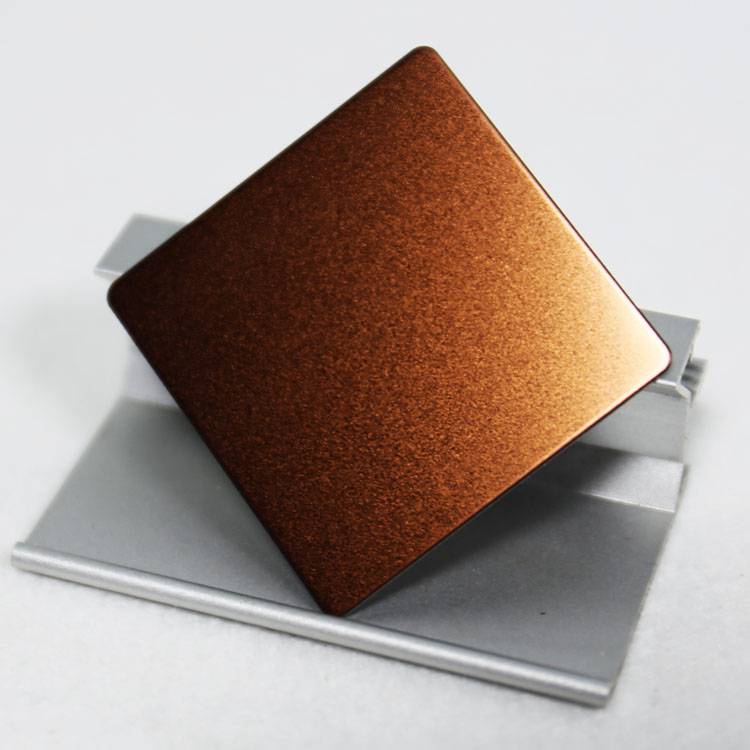

1. Architectural and Decorative Uses: PVD coating gives stainless steel plates a bold, shiny metal finishing—great for jazzing up building fronts, room accents, or cool furniture pieces.

2. Automotive and Aerospace: This PVD machine toughens up stainless steel parts like engine bits or turbine blades with a rugged metal coating that beats wear and corrosion resistance.

3. Medical Gear: The PVD coating process makes stainless steel accessories tougher and safer for medical tools.

04 Download

Magnetron sputtering coating

05 Specifications

| Model | ZJ-2624 | ZJ-2830 | ZJ-3118 | ZJ-3131 | ZJ-3531 | ZJ-3731 | |

| Chamber Size(mm) | Ф2600xH2400mm | Ф2800xH3000mm | Ф3100×H1800mm | Ф3100×H3100mm | Ф3500×H3100mm | Ф3700×H3100mm | |

| Application | Hardware industry, decoration industry, ceramics, household appliances industry | LOGO scutcheon, stainless steel show frame, stainless steel parts and sheet, etc. | |||||

| Coating Film Type | Rose gold | Champagne gold | Japanese gold | Silver | Colorful | Sapphire orchid | Rose red, black and so on |

| Vacuum Chamber | , equip with pumping system and water cooling system | Vertical door, hanging or horizontal cart structure | |||||

| Vacuum System | Sustaining Pump + Mechanical Pump + Roots Pump + Diffusion Pump | Molecule Pump(specific model according to customers' requirements) | |||||

| Vacuum | 1 set diaphragm gauge | 1 set cold cathode | 1 set pirani | ||||

| Supply Type | DC power | MF power | power(bias power,arc power) | ||||

| Ultimate Pressure | 1.0-6.0x10-4Pa | Non-loading cooling | |||||

| Arc Source | 22-28 set | 22-28 set | 26-32 set | 26-32 set | 32-48 set | 32-48 set | |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | |

| Bias Power | 60KW/1 set | 60KW/1 set | 70KW/1 set | 70KW/1 set | 80KW/1 set | 100KW/1 set | |

| Rotation | Multi-axis planetary with frequency control(can be controlled and adjusted) | ||||||

| Baking | Normal temperature ~300C, can be controlled and adjusted(PID temperature control) | ||||||

| Gas | 3 or 4 ways working gas flow control and display system matched with auto gas adding system | Ar, N2, C2H2, O2 | |||||

| Cooling Method | Water cooling circulation | equip with industrial cooling tower | industrial water chiller(refrigerating machine) | cryogenic system(customers provide) | |||

| Controlling | Manual ,half-auto | touch screen operation | PLC or computer controlled | ||||

| Supply Index | Air Pressure0.5-0.8MPa | Water Temperatures25C | Water Pressure20.2MPa | ||||

| Warning | Alarming system will work when hydropenia, over-voltage, circuit break such abnormal situation happensand carry out related protect solution and electric interlock. | ||||||

| Total Power | 165~185KW | 185~200KW | 200~225KW | 225~245KW | 245~265KW | 265~300KW | |

| Output Frequency | Voltage 380V,Frequency 50Hz(equip as customers' national electricity standard) | ||||||

| Occupation Space | 25~55㎡ | 35~55㎡ | 35~55㎡ | 45~55㎡ | 45~55㎡ | 55~75㎡ | |

| Remark | Design and produce special machine according to customers' require, can add magnetron sputtering target,MF twins target,etc. | ||||||