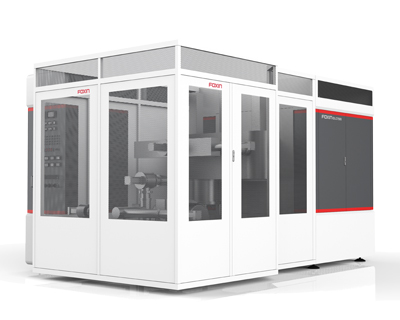

Titanium Door Handle Pvd Coating Machine

Environmental

Customization

High quality

Delivery

-

01 Overview

-

02 Benefits

-

03 Main Application

-

04 Download

-

05 Specifications

01 Overview

Titanium Door Handle PVD Coating Machine is a specialized machine use for applying PVD coatings onto furniture door handles, knobs, and other hardware made from titanium or other metals. The purpose of this machine is to provide a durable and attractive finish to the furniture hardware. The PVD coating provides scratch resistance, corrosion resistance, and a variety of color options to choose from. The machine uses a vacuum deposition process to apply the PVD coating onto the surface of the hardware

02 Benefits

Advanced Control System: The machine is equippe with an advance control system that allows for precise control over the PVD coating process.

High Efficiency: The machine is designe for high-efficiency operation, with a fast processing speed and low energy consumption.

Multiple Colors: The machine offers a variety of color options for PVD coatings, including gold, rose gold, silver, black, and other custom colors.

Automatic Operation: The machine is designe for automatic operation, with features such as automatic loading and unloading of the hardware.

Customizable: The machine can be customize to meet the specific needs of different furniture hardware manufacturers.

Color: In terms of color, the Foxin Furniture Titanium Door Handle PVD Coating Machine can provide a range of colors for the PVD coating, including gold, rose gold, silver, black, and custom colors. The exact color options may depend on the specific model and settings of the machine

03 Main Application

1、Furniture manufacturing: The machine can be used to apply PVD coating to furniture hardware, including doorknobs, handles and other accessories made of titanium or other metals. This can enhance the appearance and durability of the hardware, making it more attractive and durable.

2、Building hardware: The machine can also be used to apply PVD coatings to building hardware such as door handles, hinges and locks. This can improve the aesthetic appeal and durability of the hardware, making it more resistant to wear and tear over time.

3、Automotive industry: The machine can be used to apply PVD coating to automotive parts such as door handles, trim and other metal fittings. This can provide a durable and attractive finish to the parts, enhancing the overall appearance of the vehicle.

4、Medical industry: The machine can be used to apply PVD coatings to medical devices, such as surgical instruments, dental tools and implants. This can improve the durability and corrosion resistance of the device, making it more suitable for use in medical Settings

04 Download

Vacuum coating overview

05 Specifications

| Model(FOXIN) | FOXIN-PVD-0708 | FOXIN-PVD-0809 | FOXIN-PVD-0910 | FOXIN-PVD-1012 | FOXIN-PVD-1212 | FOXIN-PVD-1215 |

| Vacuum Chamber Size(mm) | Ф700×H800mm | Ф800×H900mm | Ф900×H1000mm | Ф1000×H1200mm | Ф1200×H1200mm | Ф1200×H1500mm |

| Industry | Watch industry, 3C industry, hardware industry, precision mold industry, tool industry, etc | |||||

| Product | Case watchband, drill, hard alloy, milling cutter, punching rod standard parts die, forming die, etc | |||||

| Coating Film Type | Titanium nitride , Titanium nitride carbide, Zirconium nitride , Chromium nitride ,Titanium aluminum nitride ,Titanium carbide | |||||

| Vacuum System | The vertical front door structure is equipped with air pumping system and water cooling system | |||||

| Vacuum Measurement | Maintenance pump + mechanical pump + Roots pump + diffusion pump or molecular pump (specific models can be configured according to customer requirements) | |||||

| Vacuum measuring system | One Pilani (MKS) One cold cathode (MKS) One thin film gauge (MKS) | |||||

| Supply Type | Dc power supply, intermediate frequency power supply, pulse power supply (bias power supply, arc power supply) | |||||

| Ultimate Pressure | No-load cold state 1.0-6.0 ×10-4Pa | |||||

| Arc Source | 6set-8set | 6set-8set | 8set-12set | 8set-12set | 10set-14set | 10set-14set |

| Arc Source | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A | 200A-300A |

| Bias Power Supply | 20KW/1set | 20KW/1set | 20KW/1set | 30KW/1set | 30KW/1set | 30KW/1set |

| Magnetron power Supply | 1set-2set | 1set-2set | 2set-3set | 2set-3set | 2set-3set | 2set-3set |

| Rotation | Multi-axis planetary male rotation, frequency control (controllable and adjustable) | |||||

| Baking Temperature | Controllable and adjustable from -300℃ to 450℃ to 600℃ (PID temperature control) | |||||

| Gas | The flow control and display system of 3-channel or 4-channel process gas is equipped with automatic gas filling system | |||||

| Gas | Argon, nitrogen, oxygen, acetylene, etc | |||||

| Cooling Method | Water cooling cycle, with industrial cooling tower or industrial chiller (chiller) or cryogenic system. (Provided by customer) | |||||

| Mode of control | PLC+ touch screen operation or computer control, manual, semi-automatic, automatic mode, | |||||

| Supply Index | Air pressure 0.5-0.8MPa, water temperature ≤25℃, water pressure ≥0.2MPa, | |||||

| Warning | Alarm the abnormal situation such as water shortage, overvoltage and undervoltage, circuit break, etc. of pump and target, and implement corresponding protection measures and electrical interlocking function. | |||||

| Total Power | 25~65KW | 45~85KW | 65~105KW | 85~115KW | 95~125KW | 100~130KW |

| Output Frequency | Voltage 380V±5%, frequency 50Hz (according to the customer's national electricity standard configuration) | |||||

| Occupation Space | 15~50m² | 15~50m² | 25~55m² | 25~55m² | 35~55m² | 35~55m² |

| Remark | Non-standard equipment can be designed and manufactured according to user requirements, and magnetron sputtering target and intermediate frequency twin pair target can be installed. | |||||