News

12 Year Pvd Coating Machine In Foxin

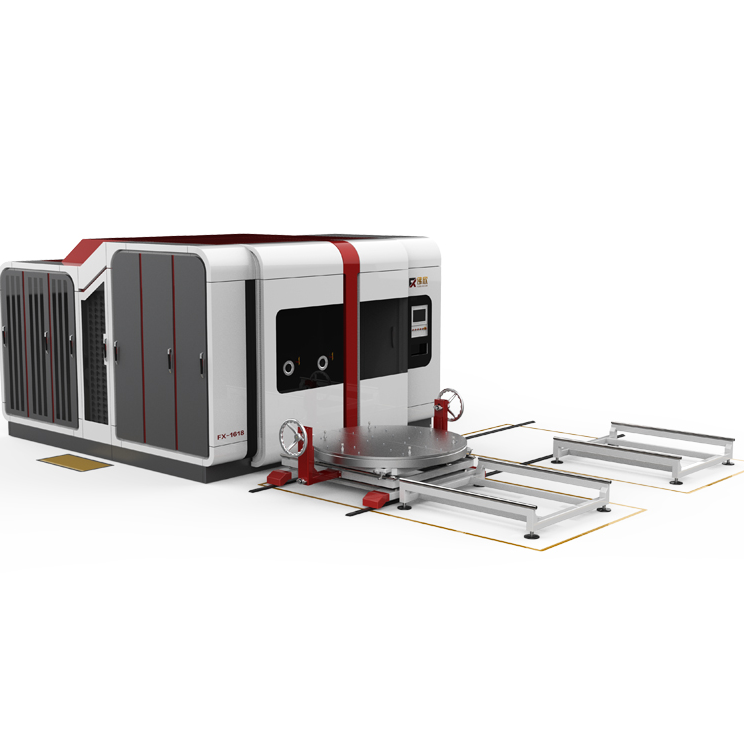

Partner with PVD Coating Equipment Suppliers for Projects

Physical Vapor Deposition (PVD) coating is a state-of-the-art technique used across various industries to enhance the durability, aesthetics, and performance of products. Among the leading PVD coating equipment suppliers, Foxin Vacuum Technology Company stands out for its innovative solutions tailored to meet diverse industrial needs. This blog delves into how Foxin’s advanced PVD coating technology benefits case watchbands, drills, and hard alloys, providing superior quality and performance enhancements.

Case Watchbands: Enhancing Durability and Aesthetics

Superior Finish and Aesthetic Appeal

Case watchbands not only serve a functional purpose but also contribute significantly to the overall aesthetics of a watch. Foxin’s multi-arc coating equipment offers a range of finishes from glossy to matte, catering to diverse consumer preferences. These finishes are not just superficial; they significantly enhance the watchbands’ appearance, making them more appealing to the eye.

In addition to traditional finishes, Foxin’s magnetron sputtering coating technology allows for unique color tones, setting your watchbands apart in a competitive market. This technology can produce a spectrum of colors, giving manufacturers the flexibility to create distinctive designs that attract consumers seeking both style and sophistication.

Foxin’s equipment ensures that these aesthetic enhancements do not compromise durability. The coatings provide a protective layer that resists scratches and wear, maintaining the watchbands’ pristine look over time. This blend of beauty and resilience is crucial for luxury and everyday watches alike.

Enhanced Resistance to Wear and Corrosion

Durability is a key concern for watch manufacturers, as consumers expect their watches to withstand daily wear and tear. Foxin’s PVD coatings significantly improve the wear resistance of case watchbands. The coatings form a hard, protective layer that guards against abrasions and scratches, extending the watchbands’ lifespan.

Corrosion resistance is another critical factor, especially for watches exposed to various environmental conditions. Foxin’s advanced coating technologies provide excellent protection against corrosion, ensuring that watchbands remain unaffected by sweat, moisture, and other corrosive elements. This feature is particularly beneficial for outdoor and sports watches, which are subject to harsher conditions.

By using Foxin’s PVD coating equipment, manufacturers can offer products that not only look great but also maintain their structural integrity over time. This combination of durability and aesthetics enhances the overall value of the watches, meeting and exceeding customer expectations.

Customizable Solutions for Diverse Needs

Every watch manufacturer has unique requirements, and Foxin recognizes this need for customization. Their PVD coating equipment is designed to be versatile, allowing for adjustments to suit specific material properties and desired outcomes. Whether you are aiming for a specific color, texture, or level of hardness, PVD Coating Equipment Suppliers like Foxin provide solutions that can be tailored to your specifications.

The flexibility of Foxin’s equipment extends to different materials used in watchbands, such as stainless steel, titanium, and ceramic. This adaptability ensures that regardless of the base material, the coatings provide optimal performance enhancements. Manufacturers can thus confidently explore innovative designs and materials, knowing that Foxin’s technology will support their vision.

Drills: Improving Performance and Lifespan

Robust Coatings for High-Stress Environments

Drills operate in some of the toughest conditions, requiring robust coatings to withstand the high stress and friction encountered during use. Foxin’s PVD coatings significantly enhance the hardness and wear resistance of drill bits, ensuring they can endure rigorous tasks without degradation. This enhancement is crucial for maintaining cutting efficiency and extending the tool’s operational life.

The coatings provided by Foxin reduce friction, which not only improves the cutting performance but also decreases heat generation during drilling. This reduction in heat helps in preserving the drill bit’s structural integrity, preventing premature wear and potential breakage. The result is a tool that performs consistently, even under demanding conditions.

Extended Tool Life and Cost Efficiency

One of the primary benefits of using Foxin’s PVD coatings on drills is the significant extension of tool life. The enhanced hardness and wear resistance mean that drill bits remain sharp and effective for longer periods, reducing the frequency of replacements. This longevity translates to substantial cost savings for industries that rely heavily on drilling operations.

In addition to the direct savings on replacement costs, extended tool life also reduces downtime associated with changing out worn tools. This efficiency gain can have a considerable impact on productivity, especially in industries where time is a critical factor. By investing in Foxin’s advanced coating technology, businesses can achieve a better return on investment through improved operational efficiency and reduced maintenance costs.

Improved Cutting Performance

The performance of a drill is directly linked to its cutting ability, and Foxin’s PVD coatings play a crucial role in enhancing this aspect. The coatings provide a smoother surface, reducing friction and allowing for more precise cuts. This improvement is particularly beneficial in applications requiring high precision and fine tolerances.

Foxin’s coatings also contribute to better chip evacuation, preventing clogging and ensuring a smoother drilling process. This aspect is vital for maintaining the efficiency and accuracy of the drilling operation, especially in materials that are prone to chip formation and accumulation. Enhanced cutting performance leads to cleaner holes and reduces the need for post-processing, further increasing productivity.

Hard Alloys: Achieving Superior Surface Properties

Excellent Adhesion and Hardness

Hard alloys are essential in various industrial applications due to their strength and durability. However, their performance can be significantly enhanced with the right surface treatment. Foxin’s PVD coatings offer excellent adhesion, ensuring that the coating remains intact even under extreme conditions. This adhesion is crucial for maintaining the integrity of the alloy components.

The hardness imparted by Foxin’s coatings is another critical benefit. The coatings provide a hard, wear-resistant surface that enhances the durability of hard alloy components. This increased hardness allows the alloys to withstand higher loads and stresses, making them suitable for demanding applications such as cutting tools, molds, and mechanical parts.

Superior Thermal Stability and Oxidation Resistance

Thermal stability is a vital property for hard alloys used in high-temperature environments. Foxin’s PVD coatings offer excellent thermal stability, ensuring that the alloys maintain their performance even at elevated temperatures. This stability is essential for applications such as aerospace, automotive, and industrial machinery, where components are subjected to extreme heat.

In addition to thermal stability, Foxin’s coatings provide superior resistance to oxidation. This property is crucial for preventing the degradation of alloy components exposed to air and other oxidizing agents at high temperatures. By protecting against oxidation, the coatings help in maintaining the mechanical properties and longevity of the alloys.

Extended Lifespan and Reliability

The combined benefits of enhanced adhesion, hardness, thermal stability, and oxidation resistance significantly extend the lifespan of hard alloy components. Foxin’s PVD coatings ensure that the components perform reliably over extended periods, reducing the need for frequent replacements. This reliability is particularly important in critical applications where component failure can lead to significant downtime and costs.

By using Foxin’s advanced coating technology, manufacturers can produce hard alloy components that meet the highest standards of performance and durability. The extended lifespan and reliability of these components contribute to overall cost savings and improved efficiency in industrial operations.

Conclusion: Foxin Vacuum Technology Company – A Trusted Partner in PVD Coating Solutions

PVD Coating Equipment Suppliers like Foxin Vacuum Technology Company stands out as a leading supplier of PVD coating equipment, offering innovative solutions that enhance the durability, aesthetics, and performance of various products. Whether it’s case watchbands, drills, or hard alloys, Foxin’s advanced coating technologies provide significant benefits, from superior finishes and wear resistance to extended tool life and improved surface properties.

By investing in Foxin’s PVD coating equipment, manufacturers can achieve higher quality products, greater efficiency, and better returns on investment. Foxin’s commitment to excellence and customization ensures that their clients receive tailored solutions that meet their specific needs, making them a trusted partner in the industry.