News

12 Year Pvd Coating Machine In Foxin

Leading PVD Coating Machine Manufacturers in China for Industrial Solutions

In recent years, China has swiftly risen as a formidable presence in the global industrial landscape, particularly excelling in the realm of advanced manufacturing technologies. Nowhere has this ascent been more evident than in the highly specialized domain of Physical Vapor Deposition (PVD) coating machine manufacturing. The remarkable progress achieved by the country in this sector is far from coincidental; rather, it is the outcome of a deliberate blend of strategic investment, pioneering innovation, and an unwavering commitment to delivering top-tier, customizable solutions. Yet, the question remains: how did China manage to secure such a pivotal role in this niche yet indispensable field of industrial technology?

China’s Emergence as a PVD Coating Machine Manufacturing Powerhouse

The expansion of PVD coating technology, which is indispensable across a wide range of industries—including automotive, electronics, medical devices, and jewelry—has been nothing short of extraordinary in recent years. As global demand for this sophisticated and versatile technology has surged, Chinese manufacturers have not only kept pace but have also firmly established themselves as leading suppliers, offering machinery that is both cost-effective and of superior quality.

China’s rise to dominance can be attributed to the remarkable agility of its manufacturers. These companies have rapidly embraced cutting-edge technologies, while at the same time maintaining a flexible approach that enables them to address the varying demands of different industries and production scales. Whether businesses require small-batch production equipment or large-scale manufacturing systems, Chinese PVD coating machine producers have proven more than capable of meeting these diverse needs, showcasing both technical expertise and adaptability.

In this highly competitive landscape, China’s manufacturers have refined their ability to produce solutions that are not only efficient but also tailored to the specific needs of each sector they serve. This strategic adaptability, combined with a relentless focus on innovation and quality, has allowed PVD Coating Machine Manufacturers in China to carve out a dominant position on the global stage, setting a new standard in the industry.

Tailoring Solutions from Small-Scale to Large-Scale Production

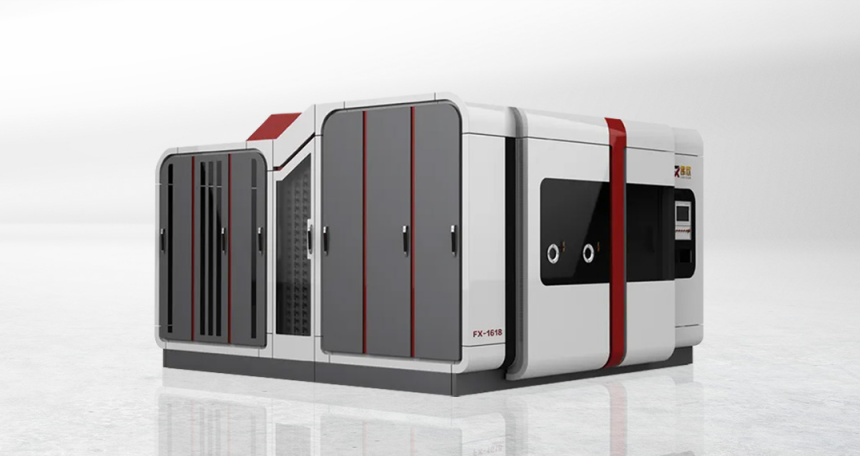

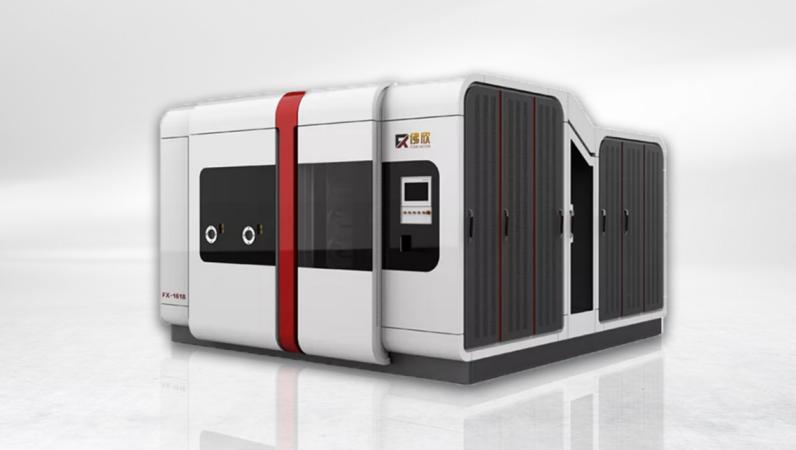

One of the primary reasons PVD Coating Machine Manufacturers in China, such as FOXIN, have garnered worldwide recognition is their ability to accommodate both small-scale and industrial-scale operations. This versatility has been instrumental in propelling Chinese companies onto the global stage, where they have gained a solid foothold by offering solutions tailored to any size of operation.

Solutions for Small-Scale Enterprises

Small-scale manufacturers, particularly those involved in specialized sectors like jewelry production, frequently demand machines that are highly precise but don’t require high-volume output. Chinese PVD machine manufacturers have been particularly proficient at catering to these needs. FOXIN, for example, has developed machines such as the Jewelry Making Metal Chain Gold Ion PVD Plating Machine, which is designed to meet the exacting standards of the jewelry sector, delivering top-tier quality coatings in smaller production runs.

For small businesses, the ability to access cutting-edge PVD technology without a significant capital investment offers a substantial competitive advantage. This capability enables them to enhance both the durability and the aesthetic appeal of their products without the need for large-scale equipment that exceeds their production demands.

Large-Scale Production Capabilities

On the other end of the spectrum, major players in sectors such as automotive, kitchenware, and electronics require machines capable of delivering high-volume output with unmatched efficiency. Chinese manufacturers have also excelled at meeting this demand by developing large-scale PVD coating solutions. An example of this is FOXIN’s Kitchenware Stainless Steel Sink PVD Coating Machine, which can efficiently coat large volumes of stainless steel products, significantly improving their durability.

The scalability of these machines has allowed Chinese manufacturers to cater to both newly emerging companies and well-established industrial leaders. Regardless of whether a company requires machines for niche, low-volume production or high-capacity manufacturing, the flexibility and reliability of Chinese manufacturers remain unparalleled.

Green Technology and Chinese Leadership in PVD Coating

The growing emphasis on sustainability and environmentally friendly solutions across all industrial sectors has positioned Chinese PVD coating manufacturers as key players in the push for green technology. By developing advanced solutions that minimize waste and reduce harmful emissions, Chinese manufacturers are not only responding to market demands but are also helping to lead the charge in eco-friendly manufacturing practices.

Innovation to Minimize Environmental Impact

While PVD coating is already a more environmentally responsible alternative to traditional coating methods like electroplating—which often involves harmful chemicals—Chinese manufacturers have gone further by innovating to make the PVD process even more sustainable. For example, FOXIN’s machines utilize thin-film technology to drastically reduce the need for hazardous chemicals during the coating process. This innovation not only minimizes the environmental impact but also results in less industrial waste, further enhancing the eco-friendliness of PVD technology.

Energy Efficiency and Cost Reduction

Beyond reducing the use of harmful chemicals, energy efficiency has become a hallmark of modern Chinese PVD coating machines. Manufacturers like FOXIN have focused on developing machines that consume less energy, aligning with the global trend toward reducing carbon footprints. By incorporating energy-saving features, these machines also lower operating costs for businesses, making them more attractive in industries where energy efficiency is a top priority.

PVD Coating for Sustainable Product Lifecycles

Another crucial aspect of PVD technology is its contribution to the sustainability of the products it coats. By significantly improving wear resistance and corrosion protection, PVD coatings enhance the longevity of materials, making them more durable and reducing the frequency of replacements. This, in turn, leads to less waste over time. FOXIN’s technology, for instance, allows companies in sectors such as automotive and construction to produce high-performance materials that are both longer-lasting and more environmentally friendly.

Exploring Customization Options with PVD Coating Machine Manufacturers in China

One of the most compelling reasons to partner with PVD Coating Machine Manufacturers in China is the wide array of customization options available. With industries ranging from high-tech electronics to decorative products relying on PVD coatings, manufacturers like FOXIN have prioritized offering tailor-made solutions that meet the exact needs of each client.

Aesthetic and Functional Customization

PVD technology’s ability to produce a vast range of custom colors and finishes is one of its standout features. In industries where aesthetics play a critical role—such as jewelry or high-end consumer goods—this capability is invaluable. FOXIN’s PVD Multi-Arc Ion Sputtering Coating Machine, for example, allows manufacturers to create bespoke colors and finishes, offering endless possibilities in terms of product differentiation.

In addition to aesthetic versatility, PVD coatings offer functional advantages, such as enhanced corrosion resistance, greater electrical conductivity, and improved material hardness. These functional benefits are crucial for sectors like aerospace and electronics, where materials are subjected to extreme conditions and must meet high-performance standards.

Industry-Specific Solutions

Every industry presents its own set of unique challenges, and Chinese manufacturers have risen to the occasion by offering solutions tailored to these diverse needs. FOXIN, for instance, provides specialized machines for industries such as medical devices, where stringent requirements for sterility and precision are non-negotiable. By delivering machines that cater to specific industry standards, PVD Coating Machine Manufacturers in China ensure their products are highly effective and fit for purpose, no matter the sector.

Streamlining the Production Process

Another advantage of collaborating with PVD Coating Machine Manufacturers in China lies in their ability to simplify and streamline the production process. Companies like FOXIN provide machines that can be integrated seamlessly into existing manufacturing lines, making the coating process more efficient and reducing overall costs. By enabling in-house coating capabilities, manufacturers reduce their reliance on external suppliers, which not only lowers expenses but also simplifies supply chain management.

Conclusion: Why China’s Leading PVD Coating Machine Manufacturers Stand Out

In conclusion, China’s ascent as a dominant force in PVD coating machine manufacturing can be attributed to its commitment to innovation, customization, and sustainability. PVD Coating Machine Manufacturers in China like FOXIN have been at the forefront of these developments, offering highly flexible machines that cater to a wide range of production scales and industry needs.

As the global demand for high-quality, sustainable coatings continues to grow, China’s manufacturers are well-positioned to lead the charge, offering advanced solutions that meet the evolving needs of industries worldwide. Whether it’s for small-scale production or industrial mass manufacturing, China’s PVD coating machine manufacturers are providing the tools necessary to thrive in an increasingly competitive global market.