News

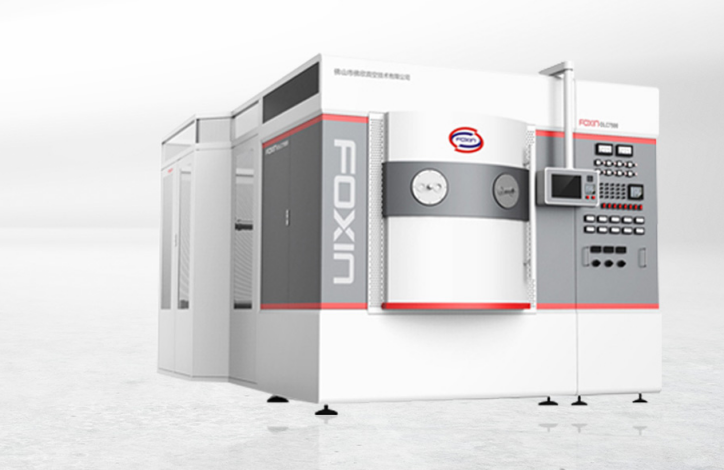

35 Year Pvd Coating Machine In Foxin

What You Need to Know About PVD Sputtering Machine Manufacturers

PVD sputtering machine manufacturers are pivotal players in the realm of advanced manufacturing technologies, specializing in the production of equipment that applies thin film coatings through Physical Vapor Deposition (PVD) processes. These machines are essential across diverse industries such as electronics, automotive, and medical devices, where they enable the deposition of precise and functional coatings.

PVD Sputtering Machine Manufacturers like Foxin Vacuum Technology Company are recognized for their innovation in developing sputtering machines that enhance product durability, improve performance, and support cutting-edge applications. Their expertise lies not only in engineering sophisticated equipment but also in providing comprehensive solutions that meet the unique demands of modern manufacturing, ensuring quality, reliability, and sustainability in coating technologies.

Introduction to PVD Sputtering Machines

Understanding PVD Technology

Physical Vapor Deposition (PVD) is a process used to deposit thin films of materials onto various surfaces. It involves the vaporization of a solid material in a vacuum environment to form a coating on a substrate. This technology is crucial in industries requiring precise, high-performance coatings.

What are PVD Sputtering Machines?

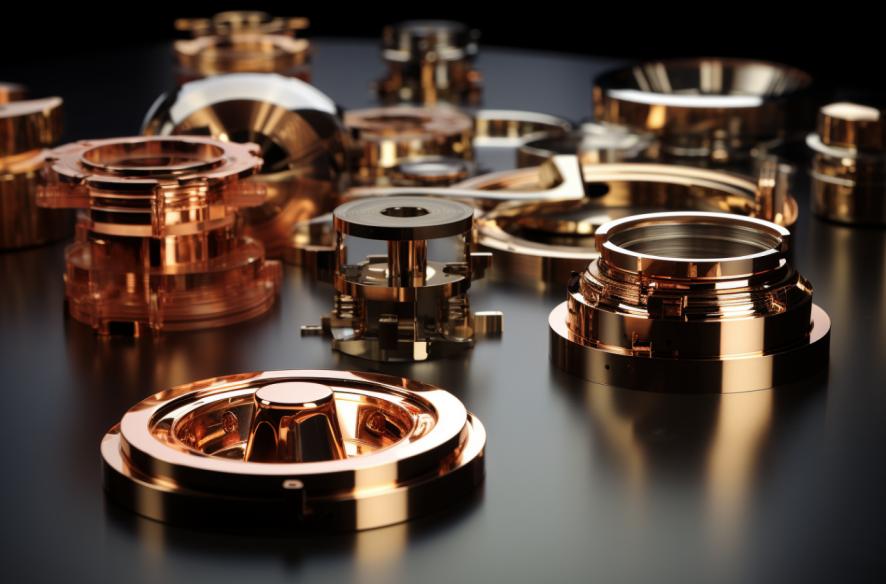

PVD sputtering machines are a type of equipment used in the PVD process. They utilize a technique called sputtering, where ions are ejected from a solid target material due to bombardment by energetic particles. These ions then deposit as a thin film on a substrate placed within the chamber. This method allows for highly controlled deposition of materials, offering benefits like uniform coating thickness and excellent adhesion.

Importance of Precision Coating in Modern Industries

In today’s industries, precision coating plays a pivotal role in enhancing product performance and durability. Whether in electronics, automotive, aerospace, or medical devices, PVD coatings provide functionalities such as corrosion resistance, wear protection, and optical enhancements. This capability not only improves product lifespan but also enhances aesthetic appeal and operational efficiency.

Latest Trends in PVD Sputtering Technology

Advances in Target Material Technology

One of the forefronts of innovation in PVD technology lies in the development of target materials. Companies like Foxin Vacuum Technology are at the forefront of incorporating advanced materials such as nanostructured coatings. These coatings offer superior mechanical, electrical, or optical properties, making them ideal for cutting-edge applications in semiconductor manufacturing, optics, and beyond.

Integration of Automation and AI

Automation and Artificial Intelligence (AI) are transforming PVD sputtering processes by enabling real-time monitoring and adaptive control. Foxin Vacuum Technology integrates smart technologies into their machines, allowing for precise adjustment of deposition parameters based on feedback. This not only enhances coating uniformity and quality but also optimizes production efficiency and reduces human error.

Growth of Environmentally Sustainable Coating Processes

In response to environmental concerns, there is a growing trend towards sustainable coating processes within the PVD industry. Foxin Vacuum Technology emphasizes eco-friendly practices by optimizing energy usage and minimizing waste generation during the coating process. Their commitment to sustainability aligns with global efforts towards greener manufacturing practices across various sectors.

Foxin Vacuum Technology Company: Leading Innovators in PVD Sputtering Machines

Commitment to Technological Advancements

Foxin Vacuum Technology Company stands out as a leading manufacturer of PVD sputtering machines, renowned for their dedication to technological advancements. With a robust R&D team, they continually push the boundaries of coating technology, developing new solutions that cater to evolving industry needs.

Customer-Centric Approach

At Foxin, a customer-centric approach is paramount. They collaborate closely with clients to understand their specific requirements and provide tailored solutions. Whether it’s for enhancing product performance or achieving unique aesthetic effects, Foxin’s machines are designed to deliver consistent, high-quality results.

Global Reach and Industry Impact

With a strong global presence, Foxin Vacuum Technology Company serves diverse industries including electronics, automotive, aerospace, and medical devices. Their machines are integral to the production processes of advanced technologies, contributing significantly to the competitiveness and innovation capabilities of their clients worldwide.

Projects Requiring PVD Sputtering Machine Manufacturers

Electronics and Semiconductors

For electronics and semiconductor manufacturing, PVD sputtering machines are indispensable in depositing thin films used in microelectronics. These coatings provide functionalities such as barrier properties against moisture and contaminants, conductivity enhancement, and optical properties for displays and sensors. Foxin Vacuum Technology Company offers advanced sputtering machines equipped with automated controls and superior material handling systems, ensuring consistent and high-quality deposition required by the electronics industry.

Automotive Industry

In the automotive industry, PVD sputtering machines are employed for applying functional coatings that enhance both aesthetic appeal and functionality. Foxin Vacuum Technology Company manufactures machines capable of depositing decorative coatings such as chrome and metallic finishes, as well as functional coatings like anti-glare surfaces and scratch-resistant layers. These coatings not only improve the visual appearance of automotive components but also provide durability against environmental factors, thereby extending the lifespan of automotive parts.

Medical Devices

Biocompatibility and durability are paramount in the medical device industry, where PVD sputtering machines are utilized to apply biocompatible coatings on implants and surgical instruments. Foxin Vacuum Technology Company specializes in providing machines that ensure the deposition of coatings with excellent adhesion and minimal material interaction, crucial for enhancing the performance and safety of medical devices. Their expertise in precision coating technologies supports advancements in healthcare by enabling the development of innovative implant materials and surgical tools.

Collaboration Needs with PVD Sputtering Machine Manufacturers

Customization and Adaptation of Coating Processes

Collaboration with PVD sputtering machine manufacturers like Foxin Vacuum Technology Company involves customizing coating processes to meet specific application requirements. Whether it’s adjusting deposition parameters for unique substrate materials or developing specialized coatings, manufacturers collaborate closely with clients to tailor solutions that optimize performance and cost-effectiveness.

Research and Development Partnerships

Innovations in materials and techniques require ongoing research and development partnerships between manufacturers and industries. Foxin Vacuum Technology Company invests in R&D initiatives to explore new materials for coatings and refine deposition techniques. By collaborating with research institutions and industry partners, they contribute to advancing coating technologies that address emerging challenges and opportunities in various sectors.

Technical Support and Training

Effective utilization of PVD sputtering machines necessitates comprehensive technical support and training for operators and engineers. Foxin Vacuum Technology Company offers training programs that educate personnel on machine operation, maintenance procedures, and troubleshooting techniques. This ensures optimal machine performance, reduces downtime, and enhances the skill set of personnel responsible for operating and maintaining PVD equipment.

Business Considerations for PVD Sputtering Machine Manufacturers

Market Dynamics and Competitive Landscape

PVD sputtering machine manufacturers operate in a dynamic market influenced by technological advancements, regulatory changes, and evolving customer demands. Foxin Vacuum Technology Company monitors market trends closely to adapt their product offerings and strategies accordingly. Their ability to anticipate market shifts and innovate ensures they remain competitive and relevant in the global manufacturing landscape.

Importance of Customer Service and After-Sales Support

Superior customer service and after-sales support are critical factors distinguishing PVD sputtering machine manufacturers. Foxin Vacuum Technology Company prioritizes customer satisfaction by offering responsive technical support, timely maintenance services, and spare parts availability. Their commitment to customer-centric practices fosters long-term partnerships and enhances customer loyalty within the industries they serve.

Emerging Opportunities in Emerging Markets and Industries

As global industries continue to evolve, new opportunities emerge in emerging markets and industries for PVD sputtering machines. Foxin Vacuum Technology Company explores these opportunities by expanding their geographic presence and adapting their product offerings to cater to specific regional and industry needs. By identifying and capitalizing on emerging trends, they position themselves as a preferred partner for manufacturers seeking reliable and innovative coating solutions.

Conclusion

In conclusion, PVD sputtering machines manufactured by companies like Foxin Vacuum Technology are instrumental in driving technological advancements and innovation across industries. With ongoing developments in target material technology, automation, and sustainability, these machines continue to evolve to meet the complex demands of modern manufacturing. As industry leaders, manufacturers of PVD sputtering machines play a crucial role in shaping the future of precision coating technologies, paving the way for enhanced product performance, durability, and environmental responsibility.