News

35 Year Pvd Coating Machine In Foxin

Advantages of PVD Stainless Steel: Strength Meets Style

As a leading supplier of PVD stainless steel machines, Foxin Vacuum Technology Company plays a pivotal role in advancing technological capabilities and sustainability practices within the industry. Their commitment to innovation and quality enables manufacturers to achieve superior surface treatments that meet the highest standards of performance and environmental responsibility. By leveraging state-of-the-art machinery and expertise, Foxin Vacuum Technology Company empowers businesses to capitalize on the economic benefits and growth opportunities offered by PVD stainless steel technology, ensuring a sustainable and prosperous future for diverse industries worldwide.

Introduction to PVD Stainless Steel

Brief Overview of PVD Stainless Steel Technology

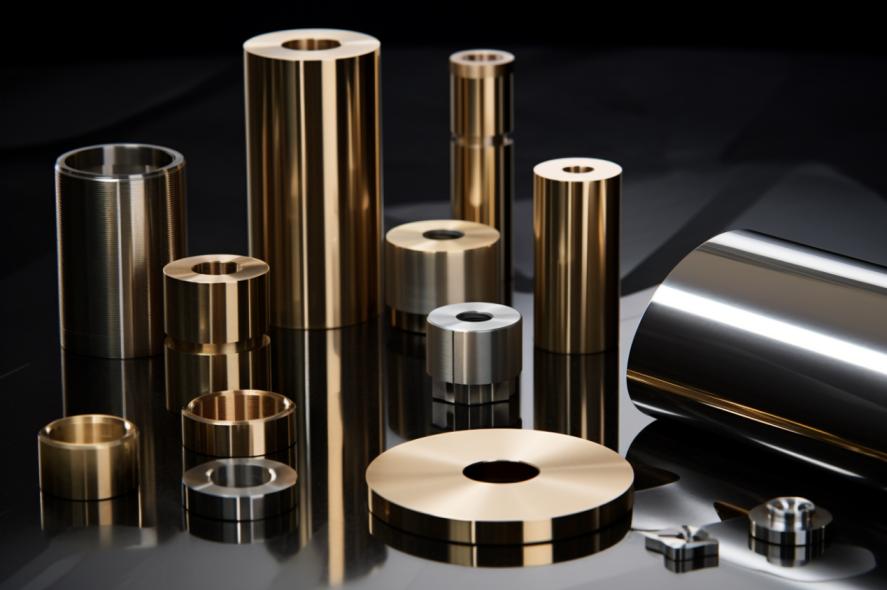

PVD (Physical Vapor Deposition) technology has revolutionized the surface treatment of stainless steel, enhancing its durability, aesthetics, and functional properties. Unlike traditional methods that rely on chemical processes, PVD involves the deposition of thin films of various materials onto stainless steel substrates in a vacuum environment. This process not only improves surface hardness and corrosion resistance but also allows for a wide range of decorative finishes.

Explanation of the PVD Process and Its Significance in Stainless Steel Applications

The PVD process begins with the preparation of the stainless steel surface through cleaning and pre-treatment. Once prepared, the substrate is placed in a vacuum chamber where materials such as titanium nitride (TiN), zirconium nitride (ZrN), or chromium nitride (CrN) are evaporated and condensed onto the surface as a thin film. This deposition enhances the stainless steel’s resistance to wear, scratches, and tarnishing while providing options for color customization and texture.

Latest Trends in PVD Stainless Steel

Emerging Trends in PVD Coatings for Stainless Steel

Recent trends in PVD coatings for stainless steel have focused on expanding color palettes and finishes to meet diverse aesthetic preferences. Manufacturers are increasingly offering custom color matching services, allowing designers and architects to achieve unique looks that blend seamlessly with different environments. Matte finishes and textured surfaces are also gaining popularity for their modern appeal and ability to hide fingerprints and smudges.

Innovations in Colors, Finishes, and Applications

Advancements in PVD technology have enabled the creation of metallic shades ranging from classic gold and bronze to contemporary black and gunmetal. These coatings not only enhance the visual appeal of stainless steel but also contribute to its functionality by improving scratch resistance and reducing maintenance requirements. Innovations in application techniques ensure uniformity and consistency across large surfaces, making PVD stainless steel suitable for architectural façades, automotive trim, and luxury consumer goods.

Sustainable Practices and Eco-Friendly Coatings

In response to environmental concerns, manufacturers are developing eco-friendly PVD coatings that minimize harmful emissions and reduce energy consumption during production. Water-based coatings and recyclable materials are becoming more prevalent, aligning with global sustainability initiatives and attracting environmentally conscious consumers and businesses.

Projects Highlighting PVD Stainless Steel

Case Studies of Notable Architectural Projects Using PVD Stainless Steel

Architects and designers worldwide are leveraging PVD stainless steel to achieve striking architectural designs. For example, the Burj Khalifa in Dubai features PVD-coated stainless steel panels that withstand the harsh desert climate while maintaining their luster and color integrity. Similarly, the Guggenheim Museum in Bilbao showcases PVD-treated stainless steel surfaces that reflect light in unique ways, enhancing the building’s aesthetic appeal.

Applications in Interior Design, Furniture, Automotive, and More

In interior design, PVD stainless steel is prized for its ability to create luxurious and durable surfaces in kitchens, bathrooms, and high-traffic areas. Furniture designers incorporate PVD coatings to produce chairs, tables, and decorative elements with lasting beauty and resilience. Automotive manufacturers utilize PVD stainless steel for exterior trim, wheels, and interior accents, combining aesthetic appeal with functional performance.

Impact of PVD Coatings on Durability and Aesthetics

The application of PVD coatings significantly enhances the durability of stainless steel by increasing resistance to abrasion, corrosion, and fading. This extended lifespan reduces maintenance costs and ensures that architectural landmarks, luxury goods, and everyday items maintain their visual appeal over time. The aesthetic versatility of PVD stainless steel allows designers to explore new possibilities in form and function, pushing the boundaries of traditional design norms.

Business Applications and Advantages of PVD Stainless Steel

Economic Benefits for Businesses Adopting PVD Stainless Steel

Businesses adopting PVD (Physical Vapor Deposition) stainless steel benefit from significant economic advantages. Initially, the investment in PVD technology and coatings translates into long-term savings due to the enhanced durability and reduced maintenance costs of stainless steel surfaces. For industries such as automotive, where aesthetics and durability are critical, PVD coatings offer a competitive edge by extending the lifespan of components and reducing replacement cycles. Moreover, the ability to customize colors and finishes enables manufacturers to meet diverse customer demands without compromising on quality or profitability.

Comparative Advantages Over Traditional Stainless Steel

Compared to traditional stainless steel, PVD-coated stainless steel offers superior performance in terms of hardness, scratch resistance, and corrosion protection. The thin film deposited during the PVD process enhances the surface properties of stainless steel, making it suitable for applications where both aesthetics and functionality are paramount. Industries ranging from architecture to consumer electronics prefer PVD stainless steel for its ability to withstand harsh environments while maintaining a pristine appearance. This competitive advantage not only enhances product longevity but also elevates brand perception and customer satisfaction.

Market Demands and Growth Opportunities

The market demand for PVD stainless steel continues to expand as industries recognize its versatile applications and aesthetic appeal. Architectural firms increasingly specify PVD-coated stainless steel for building facades and interior design elements due to its ability to create unique visual effects and withstand weathering. In the consumer goods sector, luxury brands utilize PVD coatings to differentiate their products in a competitive market, offering consumers high-end finishes that convey prestige and durability. As global infrastructure projects and urbanization drive demand for durable, low-maintenance materials, PVD stainless steel presents lucrative growth opportunities for suppliers and manufacturers alike.

Technological Advancements in PVD Stainless Steel

Advances in Coating Techniques and Machinery

Recent advancements in PVD technology have led to improvements in coating techniques and machinery, enhancing the efficiency and precision of the deposition process. Manufacturers like Foxin Vacuum Technology Company continually innovate to develop coatings that adhere uniformly to stainless steel surfaces, ensuring consistent quality across large-scale production runs. Advanced plasma sources and ion bombardment techniques optimize coating adhesion and density, further enhancing the durability and performance of PVD stainless steel in demanding applications.

Role of Automation and Digitalization in PVD Processes

Automation plays a pivotal role in modern PVD processes, streamlining production and reducing operational costs for manufacturers. Integrated robotic systems enable precise handling and positioning of stainless steel components within vacuum chambers, minimizing human error and maximizing throughput. Digitalization facilitates real-time monitoring and control of process parameters, ensuring reproducibility and consistency in coating thickness and quality. These advancements not only increase productivity but also enable manufacturers to offer customized solutions tailored to specific customer requirements with greater efficiency and accuracy.

Future Prospects for PVD Stainless Steel Technology

Looking ahead, the future prospects for it technology are promising, driven by ongoing research and development in materials science and surface engineering. Innovations in nanotechnology hold potential for further enhancing the mechanical and optical properties of PVD coatings, opening doors to new applications in emerging industries such as renewable energy and biomedical devices. As environmental sustainability becomes a focal point, manufacturers are exploring eco-friendly PVD coatings and processes that minimize environmental impact without compromising performance. These advancements position PVD stainless steel as a cornerstone technology for achieving sustainable development goals while meeting evolving market demands.

Environmental and Regulatory Considerations

Environmental Impact of PVD Stainless Steel Production

The production of it coatings generally has a lower environmental impact compared to traditional plating processes. PVD technology operates in a vacuum environment, reducing emissions of volatile organic compounds (VOCs) and hazardous chemicals. Energy-efficient coating systems and recycling programs further mitigate environmental footprint, supporting corporate sustainability initiatives and regulatory compliance. As industries prioritize eco-friendly practices, the adoption of PVD stainless steel contributes to reducing carbon footprint and promoting resource conservation throughout the product lifecycle.

Regulatory Standards and Compliance

Global regulatory standards for it production encompass emissions control, waste management, and workplace safety. Manufacturers adhere to stringent guidelines set forth by environmental protection agencies and industry associations to ensure compliance with local and international regulations. Certifications such as ISO 14001 for environmental management systems validate adherence to best practices in sustainable manufacturing, fostering transparency and accountability within the supply chain. By maintaining regulatory compliance, suppliers and end-users of it uphold corporate responsibility and build trust with stakeholders across diverse markets.

Sustainable Practices and Industry Initiatives

Sustainability initiatives within the it industry focus on continuous improvement in resource efficiency and waste reduction. Collaborative efforts among manufacturers, suppliers, and research institutions drive innovation in green technologies and lifecycle assessment methodologies. Recycling programs for used PVD coatings and recovery of precious metals contribute to circular economy principles, minimizing waste and conserving natural resources. Industry-wide partnerships promote knowledge sharing and technology transfer, accelerating the adoption of sustainable practices throughout the value chain. By embracing sustainability as a core principle, the it industry aligns economic growth with environmental stewardship, paving the way for a more resilient and responsible future.

Conclusion

For it machine suppliers like Foxin Vacuum Technology Company, their role in advancing PVD technology is crucial. By providing state-of-the-art equipment and expertise, suppliers enable manufacturers to achieve precise and consistent PVD coatings that meet the highest standards of quality and reliability. As demand grows for customizable, sustainable, and high-performance surface treatments, suppliers like Foxin Vacuum Technology Company play a pivotal role in supporting innovation across various industries. Their contributions ensure that it continues to evolve, offering endless possibilities for architects, designers, and manufacturers worldwide.