PVD Vacuum Coating Machine for Headlight Car: Illuminating the Future

In today’s automotive industry, advancements in lighting technology have revolutionized the way we perceive safety and aesthetics. Car headlights play a crucial role in enhancing visibility and ensuring road safety. To meet the evolving demands of the industry, PVD (Physical Vapor Deposition) vacuum coating machines have emerged as a game-changing solution. In this blog, we will explore the industry status, current trends, and growing needs surrounding PVD vacuum coating machines for car headlights.

PVD Vacuum Coating Machine for Headlight Car Industry Status: Shining a Light on the Market

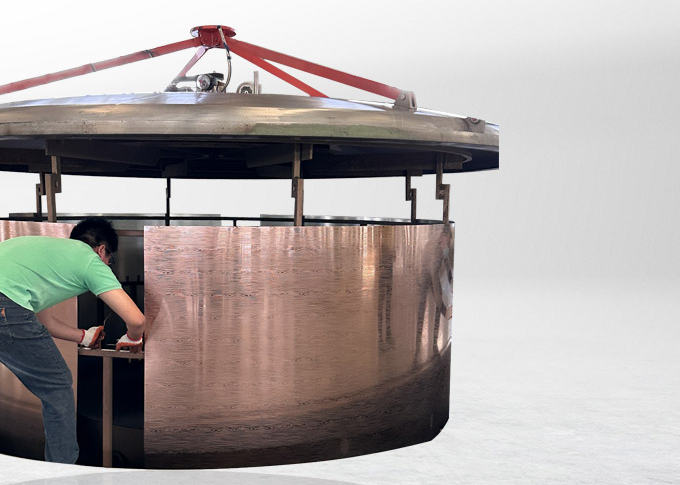

The automotive industry is witnessing a significant shift towards advanced lighting solutions, with car manufacturers aiming to provide superior illumination and design flexibility. PVD vacuum coating machines have become an integral part of this transformation. These machines allow manufacturers to apply thin films of specialized coatings onto car headlight surfaces, offering enhanced durability, color customization, and improved light transmission efficiency. This technology has gained immense popularity due to its ability to create eye-catching aesthetics while maintaining optimal performance.

PVD Vacuum Coating Machine for Headlight Car Industry Trends: Enlightening the Path to Progress

1. Increasing Demand for Customization:

As consumers seek unique and personalized experiences, the automotive industry has responded with an emphasis on customization. PVD vacuum coating machines enable manufacturers to cater to this demand by offering a wide range of color options and finishes for car headlights. Whether it’s a sleek chrome appearance or a striking metallic hue, the ability to customize headlights contributes to the overall visual appeal of the vehicle.

2. Focus on Enhanced Safety:

Road safety remains a top priority for car manufacturers, leading to a growing emphasis on headlight performance. PVD vacuum coating machines allow for the application of specialized coatings, such as anti-glare or anti-fog coatings, which significantly improve visibility during adverse weather conditions. These coatings minimize glare from oncoming vehicles and enhance the driver’s field of vision, ultimately promoting safer driving experiences.

3. Sustainable Coating Solutions:

With increasing environmental concerns, the automotive industry is striving to adopt more sustainable practices. PVD vacuum coating machines offer a greener alternative to traditional coating methods, as they produce minimal waste and utilize eco-friendly materials. By reducing the environmental impact, manufacturers can align their operations with the global sustainability agenda while providing high-quality, energy-efficient headlights.

PVD Vacuum Coating Machine for Headlight Car Industry Needs: Lighting the Way Forward

1. Advanced Coating Technologies:

As automotive lighting technology continues to evolve, there is a need for PVD vacuum coating machines to keep pace with the industry’s advancements. Manufacturers require machines that can handle new coating materials, achieve precise thickness control, and offer innovative coating techniques to create cutting-edge headlight designs.

2. Automation and Efficiency:

To meet the ever-increasing demand for car headlights, manufacturers seek automated PVD vacuum coating machines that streamline the production process. Integration of robotics, efficient material handling systems, and advanced control software can optimize production efficiency, reduce cycle times, and enhance overall productivity.

3. Collaboration and Expert Support:

Manufacturers rely on equipment providers, such as Foxin Vacuum Technology Company, to offer comprehensive support throughout the product lifecycle. Collaborative partnerships between manufacturers and machine suppliers can ensure customized solutions, regular maintenance, and technical expertise, empowering the automotive industry to continuously innovate and meet market demands effectively.

Revolutionizing Car Headlights with PVD Vacuum Coating Machine: Foxin Vacuum Technology Company

In today’s automotive industry, innovation and technology advancements have become the driving force behind enhancing vehicle performance, safety, and aesthetics. One such breakthrough is the PVD (Physical Vapor Deposition) vacuum coating machine for car headlights. Foxin Vacuum Technology Company, a leading manufacturer in this field, is at the forefront of providing cutting-edge solutions for the automotive industry.

1. Enhancing Performance with PVD Vacuum Coating Technology:

Improving Light Transmission: Headlights play a crucial role in ensuring driver safety, especially in low-light or adverse weather conditions. Foxin’s PVD vacuum coating machine enhances light transmission by applying a thin and uniform coating on headlight lenses. This specialized coating reduces glare, improves beam focus, and provides superior light dispersion, resulting in enhanced visibility and safer driving experiences.

Increasing Durability: Car headlights are exposed to harsh environmental conditions, such as UV radiation, extreme temperatures, and road debris. Foxin’s PVD vacuum coating technology offers a protective layer that significantly improves the durability and longevity of headlights. The coating acts as a shield against scratches, abrasion, and fading, thereby ensuring that the headlights maintain their optimal performance throughout the vehicle’s lifespan.

2. Aesthetic Advancements and Customization Possibilities:

Color Customization: Car manufacturers are increasingly recognizing the importance of personalization in attracting customers. Foxin’s PVD vacuum coating machines allow car headlights to be customized with a wide range of colors, giving vehicle owners the freedom to match their headlights with the overall aesthetics of their cars. This customization option not only adds a touch of uniqueness but also creates a cohesive design language.

Sleek and Uniform Appearance: The PVD vacuum coating process by Foxin ensures a uniform and seamless application of the coating layer on the headlights. This eliminates any inconsistencies or imperfections, resulting in a sleek and high-end appearance. The advanced technology employed by Foxin Vacuum Technology Company achieves a flawless finish that enhances the overall look and appeal of the car.

3. Eco-Friendly Solutions and Cost-Effectiveness:

Environmental Sustainability: In an era of increasing environmental consciousness, car manufacturers are seeking sustainable solutions without compromising performance. Foxin’s PVD vacuum coating technology is eco-friendly, using low levels of harmful emissions and reducing the need for environmentally harmful alternatives, such as traditional chrome plating. By adopting this technology, car manufacturers can contribute to a greener future.

Cost Savings: Foxin’s PVD vacuum coating machines offer cost-saving benefits to car manufacturers. The thin coating layer reduces the need for expensive raw materials, making it a more cost-effective solution compared to other coating methods. Additionally, the enhanced durability of the headlights reduces maintenance and replacement costs, providing long-term savings for both car manufacturers and vehicle owners.

Conclusion: Illuminating the Future of Car Headlights

PVD vacuum coating machines have transformed the automotive industry by offering a versatile and sustainable solution for car headlight manufacturing. With customization options, enhanced safety features, and a focus on sustainability, these machines are paving the way for brighter, more efficient, and visually stunning car headlights. As the industry progresses, continued advancements in coating technologies, automation, and collaborative partnerships will drive the development of state-of-the-art PVD vacuum coating machines, enabling car manufacturers to shine a light on the roads of the future.