Benefits & Applications: Vacuum Chamber Glass

Vacuum chamber glass, a remarkable product developed by Foxin Vacuum Technology Company, has gained significant attention in recent years. This innovative glass solution has revolutionized various industries with its unique properties and numerous applications. In this blog, we will delve into the requirements of using vacuum chamber glass and explore the advantages it offers, along with a closer look at Foxin Vacuum Technology Company, a leading manufacturer in this field.

I. Understanding Vacuum Chamber Glass:

Vacuum chamber glass is a specialized type of glass that is engineered to withstand extreme pressure differentials. It is designed to maintain a high level of structural integrity under vacuum conditions, making it ideal for applications that require hermetically sealed environments. This glass is typically composed of multiple layers, including a strong base material and thin films that enhance its performance.

II. Requirements for Using Vacuum Chamber Glass:

a) Durability and Strength:

One of the key requirements for vacuum chamber glass is durability and strength. Since it needs to withstand significant pressure differences, the glass must be robust enough to prevent any structural failures. Manufacturers like Foxin Vacuum Technology Company ensure that their vacuum chamber glass is made from high-quality materials that offer exceptional strength and long-term reliability.

b) Hermetic Sealing Capability:

Vacuum chamber glass must possess the excellent hermetic sealing capability to maintain airtight environments. This is crucial for applications where the prevention of air leakage or the entry of contaminants is essential. The manufacturing process of vacuum chamber glass involves creating a tight seal between the glass layers, ensuring the integrity of the sealed chamber.

III. Advantages of Vacuum Chamber Glass:

a) Enhanced Safety:

Vacuum chamber glass provides a safe environment for various applications. Its ability to withstand high-pressure differentials minimizes the risk of glass breakage and ensures the safety of both the equipment and personnel involved. This makes it an ideal choice for industries like aerospace, semiconductor manufacturing, and scientific research.

b) Improved Insulation:

The insulating properties of vacuum chamber glass make it highly desirable in applications where temperature control is crucial. By creating a vacuum-sealed space, the glass significantly reduces heat transfer through conduction and convection. This makes it an efficient solution for applications requiring precise temperature maintenance, such as thermal testing, cryogenics, and vacuum ovens.

c) Optical Clarity and Transparency:

I maintains excellent optical clarity and transparency, allowing for clear observation and measurement within the sealed chamber. This characteristic is particularly advantageous in scientific research and industrial processes where visual inspection or monitoring is required. It ensures accurate analysis and facilitates quality control.

IV. Foxin Vacuum Technology Company: Leading the Way:

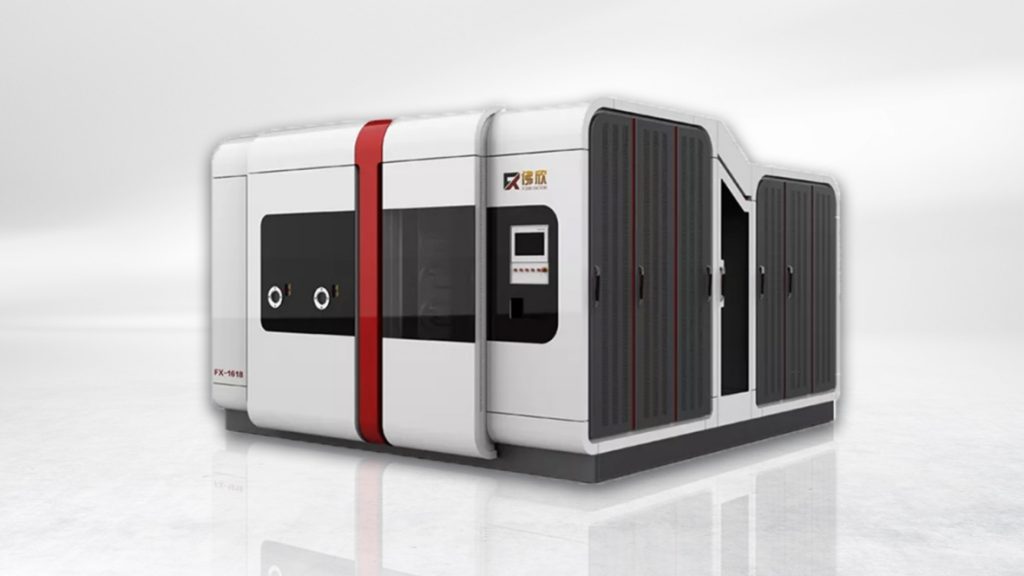

Foxin Vacuum Technology Company is a renowned manufacturer specializing in vacuum chamber glass and related products. With their cutting-edge manufacturing techniques and commitment to quality, they have established themselves as industry leaders. Their vacuum chamber glass solutions adhere to stringent standards, ensuring superior performance, durability, and reliability.

a) Superior Material for Enhanced Performance:

Foxin Vacuum Technology Company recognizes the paramount importance of using high-quality vacuum chamber glass in its manufacturing processes. This exceptional material offers remarkable benefits, such as excellent transparency, durability, and resistance to extreme temperatures and pressures. These properties enable vacuum machines to operate optimally, providing reliable performance even in the harshest conditions.

b) Ensuring Precision and Efficiency:

Precision is vital in industries where even the slightest deviation can lead to significant consequences. Vacuum machines equipped with Foxin’s vacuum chamber glass offer unparalleled precision, facilitating accurate measurements and analyses. This precision, combined with the superior efficiency of Foxin’s vacuum machines, empowers industries to streamline their processes, reduce errors, and increase productivity.

c) Versatility to Meet Industry-Specific Requirements:

Different industries have unique demands, necessitating the availability of versatile vacuum machines. Foxin Vacuum Technology Company recognizes this diversity and offers a wide range of vacuum machines tailored to specific industry requirements. From research laboratories and pharmaceutical companies to manufacturing units and semiconductor facilities, Foxin’s vacuum machines equipped with vacuum chamber glass can be customized to fulfill the most intricate needs.

d) Safety First:

When working with vacuum machines, safety is paramount. Foxin Vacuum Technology Company ensures the utmost safety by employing top-notch vacuum chamber glass in their machines. This specialized glass provides exceptional resistance to chemical corrosion, mechanical stress, and potential leaks, thereby minimizing risks and safeguarding both equipment and operators.

Ⅴ. Advancing Industries with Foxin Vacuum Technology:

Foxin Vacuum Technology Company’s utilization of high-quality vacuum chamber glass in their state-of-the-art machines has revolutionized multiple industries. Their commitment to precision, efficiency, versatility, and safety has made them a trusted name in the vacuum technology sector. As industries continue to evolve, Foxin’s vacuum machines will undoubtedly play a pivotal role in shaping the future, driving innovation, and facilitating progress on a global scale.

a) Scientific Research and Development:

The field of scientific research heavily relies on precise measurements and controlled environments. Foxin’s vacuum machines, incorporating their high-quality vacuum chamber glass, are invaluable assets in laboratories worldwide. They enable scientists to create and maintain optimal vacuum conditions, allowing for accurate experimentation, analysis, and breakthrough discoveries.

b) Pharmaceutical and Medical Applications:

Pharmaceutical and medical industries require strict adherence to quality standards to ensure product efficacy and patient safety. Foxin’s vacuum machines play a vital role in these industries by utilizing vacuum chamber glass to maintain a sterile environment, facilitating the production of medications, vaccines, and surgical instruments with the highest level of integrity.

c) Manufacturing and Semiconductor Industries:

Efficiency and precision are paramount in the manufacturing and semiconductor industries. Foxin’s vacuum machines equipped with vacuum chamber glass contribute to the smooth operation of intricate manufacturing processes. These machines aid in tasks such as material deposition, plasma processing, and quality control, ensuring products meet stringent standards while maximizing production output.

Conclusion:

Vacuum chamber glass has become an indispensable tool across a wide range of industries, thanks to its unique properties and applications. With the ability to withstand extreme pressure differentials, provide hermetic sealing, enhance safety, improve insulation, and maintain optical clarity, this specialized glass offers countless advantages. Manufacturers like Foxin Vacuum Technology Company continue to innovate and provide high-quality vacuum chamber glass, pushing the boundaries of what is possible in research, manufacturing, and technology-driven industries.