Unleashing the Power of Coating: Vacuum Machine

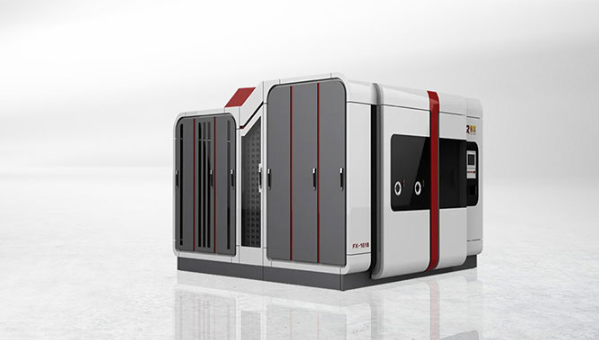

In today’s world, where advanced technology and precision play a crucial role in various industries, the demand for high-quality coatings has grown significantly. From aerospace to automotive, medical to semiconductor manufacturing, industries rely on durable and precise thin film coatings to enhance the performance and longevity of their products. FOXIN, a leading provider of vacuum machines, offers a state-of-the-art solution with their PVD Multi-Arc Ion Sputtering Coating Machine. Let’s explore the features and benefits of this remarkable piece of equipment.

How does the FOXIN-PVD Multi-Arc Ion Sputtering Coating Machine work?

The FOXIN-PVD Multi-Arc Ion Sputtering Coating Machine employs a multi-arc ion source to deposit thin films on a variety of surfaces. The process begins by loading the substrate into the vacuum chamber, which is then pumped down to a low-pressure environment. Once the desired vacuum level is achieved, the ion source is activated, and the target material is bombarded with ions. This ion bombardment causes atoms to be ejected from the target and deposited onto the substrate, forming a thin film.

What materials can be coated using the FOXIN-PVD machine?

The FOXIN-PVD Multi-Arc Ion Sputtering Coating Machine is capable of depositing a wide range of materials, including metals, alloys, ceramics, and diamond-like carbon. The specific materials that can be coated depend on the availability of the target materials and the specific requirements of the application. Common materials include stainless steel, titanium, aluminum, brass, copper, nickel, and various alloys. The machine is also capable of depositing coatings with specific properties such as high hardness, wear resistance, corrosion resistance, and optical properties.

Advantages of using the FOXIN-PVD vacuum machine

There are several advantages to using the FOXIN-PVD Multi-Arc Ion Sputtering Coating Machine:

1. High-quality coatings: The multi-arc ion source allows for the deposition of high-quality coatings with excellent adhesion, uniformity, and density. This ensures the durability and performance of the coated products.

2. Versatility: The machine can deposit a wide range of materials, making it suitable for various coating applications across different industries.

3. Efficiency: The automatic substrate loading and unloading system, combined with the advanced plasma control system, enables increased efficiency and throughput. This makes it ideal for high-volume production environments.

4. Precise control: The advanced plasma control system provides precise control over film thickness, composition, and properties. This allows for customization and meeting specific requirements.

5. User-friendly interface: The machine is designed with a user-friendly interface and control software, making it easy to operate and maintain. It simplifies the coating process and reduces the learning curve for operators.

Industries utilizing the FOXIN-PVD vacuum machine

The FOXIN-PVD Multi-Arc Ion Sputtering Coating Machine finds applications in various industries, including:

1. Automotive: Coatings for wear resistance, corrosion resistance, and decorative purposes on automotive parts, such as engine components and trim.

2. Aerospace: Coatings for improved surface hardness, wear resistance, and lubrication on aerospace components, enhancing their performance and lifespan.

3. Electronics: Coatings for improved electrical conductivity, corrosion resistance, and optical properties on electronic components, ensuring their reliability and functionality.

4. Medical: Coatings for improved biocompatibility, wear resistance, and corrosion resistance on medical devices and implants, enhancing patient safety and longevity of the devices.

5. Industrial: Coatings for wear resistance, corrosion resistance, and decorative purposes in various industrial applications, such as tools, molds, and consumer products.

Enhancing performance and longevity with Foxin vacuum technology’s FOXIN-PVD vacuum machine

1. Automotive Industry: Coatings for Enhanced Performance and Aesthetics

The automotive industry relies on coatings for a multitude of purposes. From wear resistance and corrosion protection to decorative finishes, coatings play a vital role in ensuring the durability and aesthetics of automotive parts. The FOXIN-PVD vacuum machine provides automotive manufacturers with a versatile solution. By using Physical Vapor Deposition (PVD) technology, the machine can deposit thin films of various materials onto automotive components, such as engine parts and trim. These coatings offer exceptional wear resistance, protecting the parts from friction and extending their lifespan. Additionally, the FOXIN-PVD vacuum machine can create stunning decorative finishes, giving automotive components an attractive appearance.

2. Aerospace Sector: Enhancing Performance and Lifespan of Critical Components

In the aerospace industry, where components operate under extreme conditions, coatings are crucial for improving surface hardness, wear resistance, and lubrication. The FOXIN-PVD vacuum machine excels in meeting these requirements. Its advanced capabilities allow aerospace manufacturers to apply specialized coatings that enhance the performance and lifespan of critical components. With the FOXIN-PVD vacuum machine, aerospace companies can achieve exceptional hardness and wear resistance, reducing the need for frequent replacements and maintenance. Furthermore, the machine’s precise deposition control ensures optimal lubrication properties, reducing friction and improving overall efficiency.

3. Electronics Industry: Ensuring Reliability and Functionality

In the electronics industry, coatings are essential for ensuring reliability, corrosion resistance, and improved electrical conductivity of electronic components. The FOXIN-PVD vacuum machine offers electronics manufacturers a reliable solution for achieving high-quality coatings. By utilizing the machine’s PVD technology, manufacturers can deposit thin films with excellent adhesion and uniformity. These coatings provide superior corrosion resistance, protecting delicate electronic components from environmental factors. Moreover, the FOXIN-PVD vacuum machine enables manufacturers to enhance the electrical conductivity of components, improving their overall functionality and performance.

4. Medical Sector: Enhancing Biocompatibility and Longevity of Devices

In the medical field, the need for coatings that enhance biocompatibility, wear resistance, and corrosion resistance on medical devices and implants is of utmost importance. The FOXIN-PVD vacuum machine caters to these requirements, enabling medical device manufacturers to create coatings that enhance patient safety and longevity. By using the FOXIN-PVD vacuum machine, manufacturers can deposit biocompatible coatings with exceptional wear resistance and corrosion protection. This ensures the longevity of medical devices and implants, reducing the risk of complications and the need for frequent replacements.

5. Industrial Applications: Versatile Coatings for Various Purposes

In the industrial sector, coatings find applications in a wide range of areas, including tools, molds, and consumer products. Whether it’s for wear resistance, corrosion protection, or decorative purposes, the FOXIN-PVD vacuum machine offers industrial manufacturers a versatile solution. The machine’s flexibility allows for the deposition of coatings on diverse materials, meeting the specific needs of different applications. With the FOXIN-PVD vacuum machine, industrial manufacturers can achieve superior performance and aesthetics, prolonging the lifespan of their products and satisfying customer demands.

Conclusion

In today’s advanced industries, the demand for high-performance coatings is constantly increasing. From automotive and aerospace sectors to electronics, medical, and industrial applications, the need for coatings that offer wear resistance, corrosion resistance, and improved functionality is paramount. Foxin Vacuum Technology Company, a leading manufacturer in the field, offers a cutting-edge solution with its FOXIN-PVD vacuum machine.