News

12 Year Pvd Coating Machine In Foxin

Vacuum Manufacturer: Why Partner with Foxin

In today’s fiercely competitive manufacturing industry, quality, precision, and reliability are paramount. Foxin Vacuum Technology Company stands as a leading Vacuum Manufacturer, offering advanced solutions across diverse projects. Whether it’s milling cutters or hard alloys, their expertise ensures unparalleled excellence in every endeavor. Here’s why Foxin Vacuum Technology Company is the perfect partner for your manufacturing needs:

Precision Milling Cutters: Enhancing Performance and Longevity

Milling cutters are essential for precision machining tasks, and their performance can make or break a project. At Foxin Vacuum Technology Company, they specialize in creating high-quality milling cutters that offer superior cutting efficiency and longevity. Their state-of-the-art vacuum technology ensures that the cutters maintain their sharpness and durability even under rigorous use.

When working with Foxin Vacuum Technology Company, manufacturers can expect high-precision tools that meet exact specifications. This precision is crucial in ensuring that the final products are of the highest quality, which is particularly important in industries where exact measurements and flawless finishes are essential. The company’s commitment to precision manufacturing means that every milling cutter produced is of the same exceptional quality, providing consistent performance across various applications.

Furthermore, the enhanced tool life due to superior material quality offered by Foxin Vacuum Technology Company is a significant advantage. Tools that maintain their sharpness and efficiency for longer periods reduce the need for frequent replacements, leading to cost savings for manufacturers. This durability is achieved through the company’s use of advanced vacuum technology, which enhances the material properties of the milling cutters.

Punching Rod Standard Parts: Unmatched Consistency and Strength

Punching rods are fundamental in die-cutting processes, and their reliability is critical. Vacuum Manufacturer like Foxin Vacuum Technology Company produces punching rod standard parts with exceptional strength and consistency. Their vacuum technology ensures minimal defects and high resistance to wear and tear, which translates to reliable and efficient manufacturing processes.

The uniformity in every batch of standard parts produced by Foxin Vacuum Technology Company is a testament to their meticulous manufacturing process. Consistency is key in ensuring that each punching rod performs as expected, minimizing disruptions in production. This level of uniformity also simplifies inventory management, as manufacturers can be confident that each part will meet their stringent quality standards.

Increased resistance to mechanical stress is another significant benefit of partnering with Vacuum Manufacturer like Foxin Vacuum Technology Company. Punching rods that can withstand high levels of stress without deforming or breaking are essential for maintaining production efficiency. This resistance is achieved through the company’s advanced vacuum technology, which enhances the structural integrity of the rods.

Reduced downtime and maintenance costs are additional advantages of using Foxin Vacuum Technology Company’s punching rod standard parts. The durability and reliability of these parts mean that machinery operates more smoothly and requires less frequent maintenance. This leads to more efficient production processes and lower overall costs for manufacturers.

Forming Dies: Precision Engineering for Complex Shapes

Forming dies require precision and durability to shape materials accurately. Foxin Vacuum Technology Company’s advanced vacuum manufacturing techniques ensure that their forming dies meet the highest standards of precision and durability. This leads to highly accurate and repeatable forming processes that are essential for manufacturing complex shapes.

The accuracy of Vacuum Manufacturer like Foxin Vacuum Technology Company’s forming dies ensures that manufacturers can produce components with precise dimensions and shapes. This precision is crucial in industries such as automotive and aerospace, where even the smallest deviation can lead to significant issues. The company’s commitment to quality ensures that every forming die they produce meets stringent standards, providing reliable and repeatable results.

Enhanced lifespan of dies due to superior material properties is another major benefit of working with Foxin Vacuum Technology Company. Their advanced vacuum technology improves the material characteristics of the forming dies, making them more resistant to wear and tear. This increased durability means that the dies can be used for longer periods without compromising their performance, leading to cost savings and increased efficiency for manufacturers.

Reduced material waste and improved efficiency are also significant advantages of using Foxin Vacuum Technology Company’s forming dies. The precision and durability of these dies mean that manufacturers can produce high-quality components with minimal waste. This not only reduces production costs but also aligns with sustainable manufacturing practices, which are increasingly important in today’s market.

Case Watchbands: Superior Aesthetic and Functional Quality

Manufacturing case watchbands demands both aesthetic appeal and functional reliability. Foxin Vacuum Technology Company’s vacuum technology enables the production of watchbands that are not only visually stunning but also robust and durable. Their expertise in this area ensures that manufacturers can meet the high standards required in the watch industry.

High-quality finishes that enhance the appearance of watchbands are a hallmark of Foxin Vacuum Technology Company’s manufacturing process. The company’s advanced vacuum technology allows for precise control over the surface finish, resulting in watchbands that are free from imperfections and have a premium look and feel. This attention to detail is crucial in an industry where aesthetics play a significant role in consumer choice.

Durable materials that withstand daily wear and tear are another key feature of Foxin Vacuum Technology Company’s watchbands. The company’s vacuum technology enhances the properties of the materials used, making them more resistant to scratches, corrosion, and other forms of damage. This durability ensures that the watchbands maintain their appearance and functionality over time, providing value to consumers and reducing returns for manufacturers.

Customization options to meet specific design requirements are also available from Vacuum Manufacturer like Foxin Vacuum Technology Company. The company’s flexible manufacturing processes allow them to produce watchbands in a variety of styles, sizes, and finishes, enabling manufacturers to offer a wide range of products to their customers. This ability to customize is essential in a market where consumers are looking for unique and personalized items.

Drills: High Performance for Diverse Applications

Drills are used across numerous industries, and their efficiency is paramount. Foxin Vacuum Technology Company manufactures drills that offer superior performance and longevity, thanks to their advanced vacuum technology. Partnering with Foxin Vacuum Technology Company ensures that manufacturers have access to drills that maintain their sharpness over extended use, providing consistent and reliable performance.

The ability of Foxin Vacuum Technology Company’s drills to maintain their sharpness is a significant advantage for manufacturers. Sharp drills are essential for efficient and accurate drilling, and tools that retain their sharpness for longer periods reduce the need for frequent replacements. This leads to cost savings and increased productivity, as manufacturers can rely on their tools to perform consistently.

High resistance to heat and wear is another important feature of Foxin Vacuum Technology Company’s drills. Drilling generates significant heat, and tools that can withstand high temperatures without losing their hardness or becoming damaged are essential for maintaining performance. The company’s vacuum technology enhances the heat resistance and wear properties of their drills, ensuring they perform well even under demanding conditions.

Versatility for various drilling applications is also a key benefit of partnering with Vacuum Manufacturer like Foxin Vacuum Technology Company. Their drills are suitable for a wide range of materials and applications, making them a valuable addition to any manufacturer’s toolkit. This versatility allows manufacturers to use the same high-quality tools across different projects, simplifying inventory management and reducing costs.

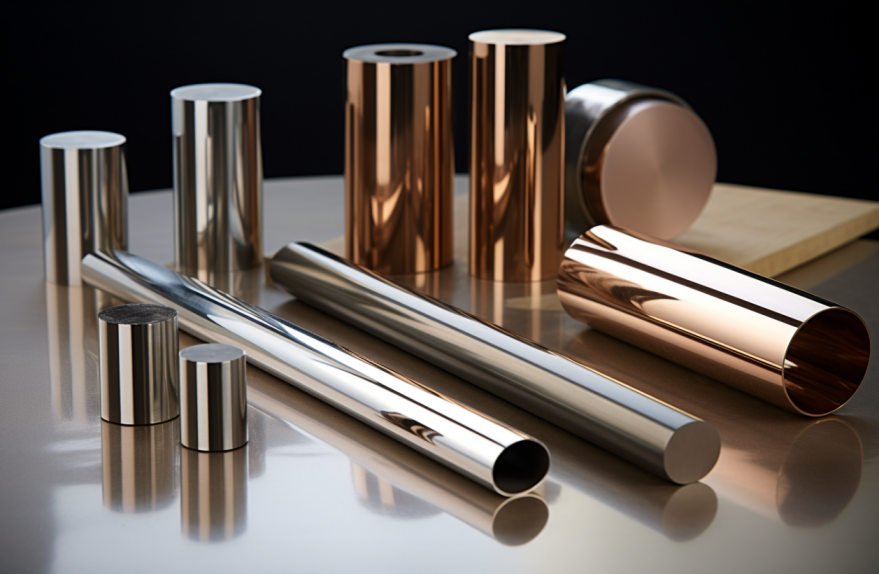

Hard Alloys: Exceptional Strength and Durability

Hard alloys are critical for tools and components that require extreme durability. Foxin Vacuum Technology Company excels in producing hard alloys that meet stringent quality standards. Their vacuum technology enhances the properties of hard alloys, resulting in materials with increased hardness and resistance to deformation.

The increased hardness of Foxin Vacuum Technology Company’s hard alloys is a significant benefit for manufacturers. Harder materials are more resistant to wear and can maintain their shape and performance over longer periods. This is particularly important for tools and components that are subject to high levels of stress and wear, such as cutting tools and mechanical components.

Superior wear resistance for extended tool life is another major advantage of using Foxin Vacuum Technology Company’s hard alloys. Tools and components made from these materials are less likely to wear out or become damaged, reducing the need for frequent replacements and maintenance. This leads to cost savings and increased efficiency for manufacturers, as they can rely on their tools to perform consistently over time.

Consistent quality across all produced batches is also a key feature of Foxin Vacuum Technology Company’s hard alloys. The company’s advanced manufacturing processes ensure that every batch of material meets the same high standards, providing manufacturers with reliable and consistent performance. This level of quality control is essential in industries where precision and reliability are critical.

Conclusion: Why Choose Foxin Vacuum Technology Company?

Vacuum Manufacturer like Foxin Vacuum Technology Company is dedicated to delivering excellence in every product they manufacture. Utilizing cutting-edge vacuum technology and rigorous quality control measures, they ensure that every tool and component meets the highest standards of precision, durability, and performance. By partnering with Foxin Vacuum Technology Company, manufacturers benefit from advanced manufacturing techniques, customized solutions, a reliable supply chain, and expert support.